How to Improve Operational Efficiency: Practical Tips

Learn effective ways on how to improve operational efficiency. Boost productivity and reduce costs with our expert strategies.

In simple terms, improving operational efficiency is about getting better results from the resources you already have. It’s a methodical process of cutting out waste, fine-tuning your workflows, and giving your team the tools to work smarter, not just harder. This shift turns a reactive business into a resilient one.

Why Operational Efficiency Is Your Competitive Edge

In a tough economy, asking your team to simply work longer hours isn’t a viable strategy for growth. Your true competitive advantage comes from operational efficiency—the ability to achieve more with your existing assets. It’s what drives profitability, boosts customer satisfaction, and builds a business capable of navigating market ups and downs.

For many Australian businesses, the pressure is on. Rising costs, stubborn inflation, and ongoing labour shortages are creating a challenging environment. This is where a laser focus on efficiency moves from being a ‘nice-to-have’ to a fundamental survival tactic. The aim is to build resilience, ensuring your organisation can not only survive economic turbulence but actually come out stronger.

Making It Real: Beyond the Buzzwords

“Operational efficiency” can sound like a vague corporate buzzword, but its impact is very real and measurable. It tackles the exact problems that keep business leaders up at night. When you genuinely improve how your business runs, the benefits show up clearly on your balance sheet and in your company culture.

So, what are the key advantages you can expect?

- Lower Operational Costs: When you get rid of redundant tasks and make better use of your resources, you naturally reduce waste and needless spending.

- Higher Productivity: Your team can get more done in less time once their workflows are cleared of frustrating bottlenecks and inefficiencies.

- Better Service Quality: Smooth processes almost always mean quicker delivery and fewer mistakes, which directly translates to a better customer experience.

- Improved Business Agility: A well-oiled operation can pivot much faster to seize new opportunities, adapt to market shifts, or handle unexpected problems.

These outcomes aren’t just happy accidents. They’re the direct result of a focused, strategic effort to improve how your business operates from the ground up. To see how this works in practice, exploring some proven strategies to improve workflow efficiency offers some great, actionable ideas.

To properly enhance how your business operates, you need to concentrate on a few core pillars. The table below outlines these foundational areas.

Core Pillars of Operational Efficiency Improvement

| Pillar | Description | Key Focus Area |

|---|---|---|

| Process Optimisation | Analysing and refining existing workflows to eliminate waste, redundancy, and bottlenecks. | Workflow mapping, standardisation, automation of repetitive tasks. |

| Technology Integration | Implementing the right software and tools to support efficient processes and data-driven decisions. | AI/Automation tools, CRM/ERP systems, communication platforms. |

| People and Culture | Empowering employees with the skills, knowledge, and mindset to contribute to continuous improvement. | Training and development, fostering a culture of feedback, clear communication. |

| Performance Measurement | Using data and KPIs to track progress, identify areas for improvement, and validate changes. | Setting clear metrics, regular performance reviews, data analysis. |

By addressing each of these pillars, you create a holistic strategy that drives sustainable and meaningful improvements across the entire organisation.

A focus on efficiency is fundamentally about creating a more robust and sustainable business model. It’s the strategic choice to invest in processes and systems that will pay dividends long after the initial effort is complete.

This isn’t just theory; it’s a clear trend in today’s business world. Australian companies are increasingly adopting new tech to get an edge. Facing economic headwinds, leaders are making it a priority to implement systems that boost operational efficiency. In fact, 1 in 3 executives now consider productivity growth their number one concern. This guide will give you the clear roadmap needed to get there.

Conducting an Honest Operational Health Check

Before you can genuinely improve how your business runs, you need a crystal-clear picture of where it stands right now. This isn’t about guesswork or assumptions; it’s about conducting a thorough, honest operational health check. You can’t fix problems you can’t find, and this deep dive is your first step to uncovering what’s really happening behind the scenes.

The aim here is to build an objective, detailed map of your current reality. It’s time to move past generic advice and really get into the weeds to identify those hidden bottlenecks, redundant tasks, and quiet drains on your resources that frustrate your team and cost you money.

Starting With a Visual Source of Truth

One of the most powerful techniques I’ve seen work time and again is process mapping. This is more than just drawing a few boxes and arrows on a whiteboard; it’s about creating a visual source of truth for your core workflows. A particularly effective method for this is the swimlane diagram.

This kind of map organises a process into horizontal or vertical “lanes,” where each lane represents a specific department, team, or even an individual. By visually tracking a task as it moves from one lane to another, you can instantly see where handoffs are clumsy, where delays are piling up, and exactly who is responsible at each stage.

Imagine a retail business mapping its order fulfilment process. You might have lanes for “Online Store,” “Warehouse Picking,” “Packing Station,” and “Shipping.” When you trace a single order’s journey, you might discover that while picking is lightning-fast, orders consistently stall at the packing station. This creates a major bottleneck that delays shipping and ultimately sours the customer experience. This kind of visual clarity is the crucial first step toward solving the problem.

Gathering Both the “What” and the “Why”

A truly comprehensive health check needs more than just diagrams. You have to pair the hard data with human insights to get the complete story.

Quantitative Data (The “What”)

This is all about objective, measurable information that tells you what is happening inside your processes. The key metrics you should be gathering include:

- Cycle Time: How long does it take to complete a process from the very beginning to the very end?

- Throughput: How many units or tasks are completed in a given timeframe?

- Error Rates: What percentage of outcomes have mistakes or defects that force you to do rework?

- Resource Utilisation: How effectively are your people, software, and equipment being used?

Qualitative Data (The “Why”)

This is where you find the context behind the numbers. It explains why the metrics look the way they do. You can get this from:

- Employee Interviews: Just talk to your people on the front lines. They almost always have the sharpest insights into daily frustrations and hidden inefficiencies.

- Customer Surveys: Find out how your operational hiccups are actually affecting the people who keep you in business.

- Manager Feedback: Get that broader, higher-level perspective from those overseeing the teams and processes.

This dual-pronged approach stops you from making changes based on half the story. A high error rate (the quantitative “what”) might be explained when an employee interview (the qualitative “why”) reveals that the software interface is clunky and confusing, leading to constant mistakes.

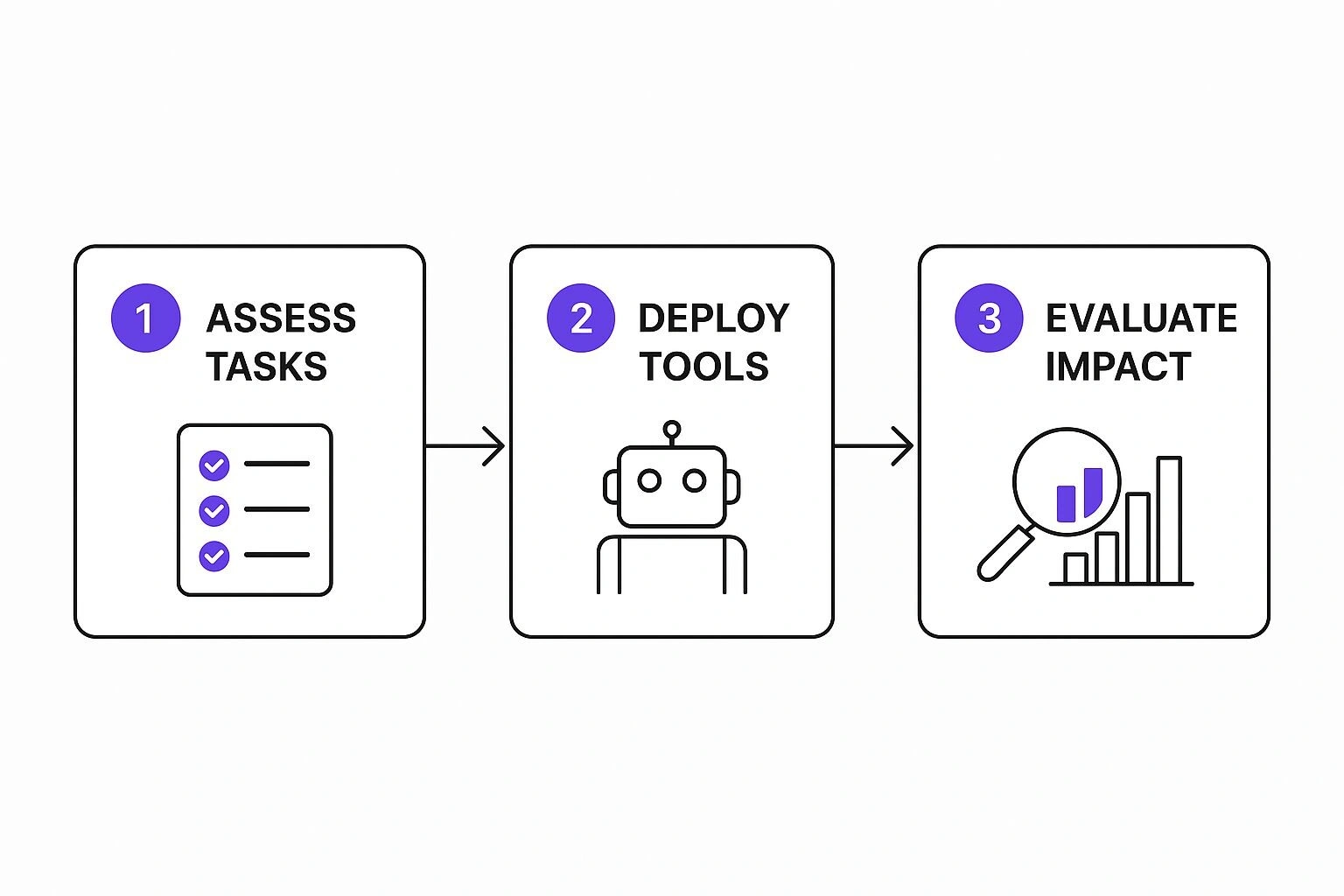

The infographic below shows how these findings fit into the broader improvement cycle.

As the visual makes clear, assessing your tasks is the foundational step you must take before even thinking about new tools or measuring their impact. If you skip a proper assessment, you’ll almost certainly end up automating the wrong things.

Benchmarking Against National Performance

Getting a grip on your internal inefficiencies is the main goal, but it also helps to see how you stack up against the wider economic backdrop. Here in Australia, multifactor productivity (MFP) is a key economic indicator that measures operational efficiency by looking at inputs like labour and capital.

Research from the Productivity Commission has shown that many Australian industries, from manufacturing to utilities, have ongoing inefficiencies where their actual MFP doesn’t meet its potential. This points to a significant, widespread opportunity for businesses to sharpen their operations. You can explore the full productivity analysis from the Australian Government to see these trends for yourself.

By running your own health check, you’re taking the first real step toward closing your own productivity gap. The insights you gain from this audit will be the foundation for every single action you take, ensuring your efforts are targeted, effective, and driven by data, not just hunches.

Upskilling Your Workforce for Peak Performance

While the right tech and automation can deliver incredible gains, it’s a mistake to overlook the human element. Your people are, and always will be, your single greatest asset in the quest for operational efficiency. You only unlock real, lasting performance improvements when your team is properly equipped and aligned with your newly optimised processes.

Thinking about your people can’t be an afterthought. It needs to be a core part of your strategy, ensuring any changes you make are embedded deeply into the way your business runs. This is about more than just rolling out new software; it’s a deliberate effort to upskill your team so every person has the confidence and capability to excel in their role.

Identifying and Closing Critical Skills Gaps

The starting point is a frank assessment of where your team stands today. A skills gap analysis is simply a methodical way of comparing the skills your business needs to hit its targets against the skills your people actually have. This isn’t about finding fault. It’s about spotting opportunities for growth that directly connect to your bottom line.

Let’s say you’ve just spent weeks optimising your financial reporting process, but a bottleneck stubbornly remains. The issue might not be the process at all. It could be that your finance team, while brilliant with numbers, lacks the advanced spreadsheet or data visualisation skills to get the most out of the new system.

Once you know where the gaps are, you can put targeted training in place to fix them. There are a few ways to tackle this:

- Internal Workshops: Led by your own subject matter experts, these are great for hands-on, highly relevant training.

- External Certifications: For specialised or technical skills that need a more formal, structured approach.

- Mentorship Programs: Pairing junior staff with experienced team members is a brilliant way to transfer institutional knowledge.

Another powerful tactic I’ve seen work wonders is cross-training. Teaching employees to handle tasks outside their usual duties builds a more flexible and resilient team. When people can cover for each other, you avoid a single absence grinding an entire workflow to a halt.

Aligning Roles With Optimised Processes

With skills development underway, the next logical step is to ensure everyone’s roles and responsibilities are crystal clear. Ambiguity is the enemy of efficiency. When people aren’t sure what they’re meant to be doing or how their work fits into the bigger picture, you get duplicated effort, missed handoffs, and a whole lot of confusion.

Updating job descriptions is a practical way to formalise these new expectations. Clearly spell out the new tasks, the tools everyone is expected to master, and the specific KPIs they’ll be measured against. This clarity gives people purpose and helps them see how their individual contributions drive the organisation’s success. For anyone looking to dig deeper into this, our guide on strategic business process improvement is a great resource.

The ultimate goal here is to foster a culture of continuous improvement. You want to create an environment where employees feel not just permitted, but actively encouraged to flag inefficiencies and suggest better ways of working. When your team takes ownership of their processes, you create a powerful, self-sustaining engine for operational excellence.

This proactive approach is especially critical right now. Labour shortages are a serious challenge across many Australian industries, causing very real disruptions. A report from the Ai Group found that 71% of industry leaders expect these shortages to impact their operations, leading to a projected 28% drop in operational efficiency. By investing in the team you already have, you build capability from within and make your entire organisation more resilient to these external pressures. You can explore this further in the full Ai Group outlook.

Weaving in Technology and Automation Smartly

Jumping on every new piece of tech without a clear plan is a surefire way to burn through your budget and frustrate your team. Smart implementation isn’t about chasing trends; it’s about carefully selecting the right tools to fix the specific operational headaches you’ve already pinpointed. The idea is to match the solution to the pain point, not the other way around.

Your journey into automation doesn’t need to start with a massive, all-encompassing system. In my experience, many businesses get fantastic results by starting small. Think simple workflow automation tools that take care of those repetitive, time-sucking administrative jobs. This immediately frees up your people to concentrate on the work that actually needs their expertise and problem-solving skills.

As your business matures and its operations become more intricate, you can then start exploring more powerful, integrated solutions. This is where big-hitters like Customer Relationship Management (CRM) and Enterprise Resource Planning (ERP) systems enter the picture. These platforms are built to act as the central hub for your core business functions, tying everything together from sales and marketing to finance and inventory.

Choosing the Right Tools for the Job

Let’s be honest, picking new software can feel like a mammoth task. The market is flooded with options, and it’s all too easy to be dazzled by flashy features that you don’t actually need. The best way to sidestep this pitfall is to use a structured evaluation process. This forces you to look beyond the sticker price and assess the real, long-term value of a potential solution.

When you’re weighing up different technologies, here are the non-negotiables to assess:

- Scalability: Will this tool grow with you? What works for a team of ten could become a serious bottleneck for a team of fifty.

- Integration Capabilities: Does it play nice with the systems you already rely on? A tool that lives on its own island often creates more manual work than it eliminates.

- User-Friendliness: Is it actually intuitive for your team? A powerful piece of software is practically useless if the learning curve is so steep that nobody wants to use it.

- Total Cost of Ownership (TCO): Look past the subscription fee. You need to factor in the costs of implementation, training, ongoing maintenance, and any customisation work.

This methodical approach helps you avoid “shiny object syndrome” and ensures your tech investments deliver a genuine return. To really get the most out of new tech for operational efficiency, it pays to have a well-defined digital transformation roadmap.

Putting AI to Work for Smarter Operations

Artificial intelligence has moved from sci-fi to a genuinely practical tool that can drive some serious efficiency gains right now. AI really shines when it’s pointed at tasks involving pattern recognition, prediction, and data analysis on a scale that’s simply out of reach for humans.

Take a retail or manufacturing business, for instance. AI can be used for predictive inventory management. Instead of just looking at past sales, AI algorithms can analyse current trends, seasonality, supply chain disruptions, and even weather patterns to forecast demand with incredible accuracy. This directly slashes the costs tied to both overstocking and running out of popular items.

Another great application is in customer service. AI-powered chatbots can handle a massive volume of common customer questions 24/7, offering instant answers on order status, product details, or return policies.

This isn’t about replacing your human support team. It’s about freeing them from the repetitive, low-level queries so they can focus their valuable time and expertise on resolving the more complex or sensitive customer issues that absolutely require a human touch.

A Phased Approach to Automation

The most successful rollouts I’ve seen are rarely a “big bang” event. A phased approach is your best friend here—it lets you manage risk, get crucial feedback, and show tangible results at every stage. A great strategy is to start by automating low-risk, high-impact processes first.

These “quick wins” are fantastic for building momentum and getting your team comfortable with new ways of working. Once you have a few successful automations up and running, you can tackle the more complex, core business processes with much more confidence.

This iterative cycle is the secret to making technology truly work for you. If you’re looking to get started, understanding the fundamentals is key. Our deep dive on how to automate business processes offers a practical framework to help you map out your own journey. By taking a measured and strategic approach, you ensure every new piece of tech you bring in is a deliberate step towards a more efficient and resilient operation.

Tracking Success and Fostering Continuous Improvement

Putting new processes and technology in place is a massive step forward, but it’s definitely not the end of the road. I’ve seen too many businesses celebrate a successful launch, only to let the momentum fizzle out. Real operational efficiency isn’t a project with a finish line; it’s a marathon of constant refinement.

To make sure your hard-earned gains actually stick, you need a solid system for measuring what’s working and a commitment to always getting better. Without this, you’re just guessing. You won’t know which changes truly moved the needle and which were just a waste of time and money. This is where Key Performance Indicators (KPIs) become your best friend—they give you the hard data to prove your efforts are paying off.

Choosing the KPIs That Actually Matter

Picking the right KPIs is absolutely critical. Vague, generic metrics are useless. The indicators you choose must tie directly back to the specific process you set out to improve.

So, if you just overhauled your entire client onboarding process, you shouldn’t be obsessing over website traffic. You should be tracking things like time-to-onboard, client satisfaction scores in the first 30 days, or the number of support tickets from new customers.

Think back to the original problem. Were you trying to become faster? Cheaper? More accurate? Your KPIs need to reflect those goals. For a really practical look at how to align your metrics with your business objectives, our article on how to measure operational efficiency is a great resource.

To give you a clearer idea, here’s a look at some practical KPIs you might track. This isn’t an exhaustive list, but it shows how you can measure the impact of your improvements across different parts of the business.

Key Metrics for Tracking Operational Efficiency Gains

| Metric Category | Example KPI | What It Measures |

|---|---|---|

| Time Efficiency | Cycle Time Reduction | The total time you’ve managed to shave off a process, from start to finish. |

| Cost Efficiency | Cost Per Unit | The real-world expense of producing one item or delivering one service. |

| Quality & Accuracy | Error Rate | The percentage of outputs that have mistakes or need to be fixed. |

| Customer Impact | Customer Satisfaction (CSAT) Score | How happy your customers are with your service or product after the changes. |

Once you have your metrics, the real work of building a culture of improvement begins.

Building a Culture of Non-Stop Improvement

Having the data is one thing; using it to drive change is another entirely. This is where you need to build a culture where getting better is just part of everyone’s job. Frameworks like the Plan-Do-Check-Act (PDCA) cycle are fantastic for this because they create a simple, repeatable loop for making smart, incremental changes.

Here’s how it works in practice:

- Plan: Spot an area for improvement and map out a change.

- Do: Roll out the change, but keep it small-scale at first.

- Check: Dig into the data. Did your KPIs move in the right direction?

- Act: If the change worked, implement it more widely. If it didn’t, it’s back to the drawing board to figure out why.

This cycle stops you from making massive, risky changes based on a hunch. It encourages a more scientific, data-backed approach to getting better.

The most crucial part of this culture is the feedback loop. Regular meetings to go over the performance data are non-negotiable. But these meetings aren’t about pointing fingers. They’re about celebrating wins and working together to tackle the next set of challenges.

When your team sees how their ideas directly affect the KPIs, they become far more invested in finding the next opportunity. It turns efficiency from a top-down order into a shared mission. This is what separates businesses that see a temporary boost from those that achieve genuine, lasting operational excellence.

Frequently Asked Questions About Operational Efficiency

As leaders start thinking about how to improve operational efficiency, a few questions always come up. It’s a journey that can feel a bit overwhelming at first, but getting straight answers to these common concerns can make all the difference. Let’s tackle those lingering questions head-on so you can move forward with a clear plan.

We’ll get into everything from the initial time commitment and getting your team on board, to what the real-world costs actually look like. The goal here is to demystify the process and give you the practical knowledge you need.

How Much Time Does This Actually Take?

This is usually the first thing people ask, and the honest answer is: it depends. A deep-dive audit and mapping out a single, simple process might only take a few weeks. But if you’re looking at a large, complex organisation with multiple interconnected workflows, you could be looking at a couple of months for just the initial phase. It all comes down to the scope you set.

What’s more important to realise, though, is that improving operational efficiency isn’t a project you finish. It’s a shift towards a culture of continuous improvement.

The big push to find major bottlenecks and roll out some “quick win” solutions might take a quarter. But the real, lasting change comes from weaving these practices into your day-to-day operations. It’s a marathon, not a sprint.

My advice? Start small. Don’t try to boil the ocean by overhauling the entire company at once. Pick one high-impact, frustrating process, fix it, and let the momentum from that success carry you into the next initiative.

Will My Team Resist These Changes?

Employee pushback is a legitimate worry, but in my experience, it’s almost always preventable. Resistance usually comes from a fear of the unknown, worries about job security, or just plain frustration with changes that aren’t communicated well. The way around this is to make your team part of the solution from the very beginning.

This isn’t about changes happening to them; it’s about changes happening with them.

- Bring them into the audit: Your frontline staff know the real-world problems better than anyone. When you’re mapping processes, ask for their insights. They’ll point out inefficiencies you never would have seen from the boardroom.

- Explain the “why”: Be transparent about the goals. It’s not about “cutting costs” – it’s about “removing frustrating roadblocks so we can all do our best work.”

- Train them properly: Don’t just dump new software on them and hope for the best. Invest in good training to build their confidence and competence with the new tools.

When your team sees that these changes are designed to make their jobs less frustrating and more rewarding, they’re far more likely to become champions for the cause, not obstacles.

What Are the Real Costs Involved?

When you budget for an efficiency drive, the costs fall into two buckets: direct and indirect. You need to account for both.

Direct Costs:

- Technology: This is your software subscription for a CRM or automation platform, plus any one-time setup fees.

- Training: The budget for workshops, online courses, or any certifications needed to get your team up to speed.

- Consulting: If you bring in outside experts for guidance, their fees are a direct cost.

Indirect Costs:

- Employee Time: The hours your team spends in audits, training sessions, and learning new processes is a very real, though indirect, cost.

- Temporary Disruption: As you roll out new systems, you might see a short-term dip in productivity. It’s smart to plan for this.

The crucial mindset shift here is to see this as an investment, not an expense. A well-planned initiative will deliver a clear return by cutting waste, lowering operational costs, and boosting output, ultimately paying for itself many times over.

How Does This Improve Customer Satisfaction?

This is a fantastic question because it connects what you do internally to what your customers experience externally. When you improve operational efficiency, your customers feel the positive effects, even if they never see what’s happening behind the scenes.

A smoother internal process leads to fewer mistakes, faster delivery, and more consistent quality. Think about it: if you optimise your order fulfilment workflow, customers get their products faster and with fewer errors. If you use a chatbot to handle routine support questions, your human agents are freed up to give better, more in-depth help on complex issues.

At the end of the day, a well-oiled machine creates a seamless customer journey. Less friction for your team directly translates to a better experience for your customers, which is a massive driver of loyalty and repeat business. Improving how you work on the inside is one of the best ways to strengthen your customer relationships on the outside.

Ready to unlock your business’s true potential? Osher Digital specialises in building the custom automation and AI agents that eliminate bottlenecks and drive sustainable growth. We partner with you to analyse your unique processes and implement the precise technology needed to improve accuracy, cut costs, and scale your operations effectively. Discover how we can transform your workflows by visiting https://osher.com.au.

Jump to a section

Ready to streamline your operations?

Get in touch for a free consultation to see how we can streamline your operations and increase your productivity.