AI in Manufacturing Explained: A Practical Guide to Efficiency

Artificial intelligence in manufacturing is less about futuristic robots and more about making your entire operation smarter. It’s about giving your production line a brain. This brain can predict problems, spot the tiniest defects, and constantly find better ways to get things done. It’s the bridge between raw data and real-world results. What AI in […]

Artificial intelligence in manufacturing is less about futuristic robots and more about making your entire operation smarter. It’s about giving your production line a brain. This brain can predict problems, spot the tiniest defects, and constantly find better ways to get things done. It’s the bridge between raw data and real-world results.

What AI in Manufacturing Really Means

Forget the jargon for a moment. Picture your factory not just following a rigid set of instructions but actively learning and adapting on its own. That’s the real idea behind AI in manufacturing. It’s not about replacing your experienced team. It’s about giving them super-intelligent tools that make their jobs easier and their decisions more impactful.

Think of AI as a tireless assistant that never sleeps. It’s constantly monitoring every machine, every process, and every variable. This assistant can sift through mind-boggling amounts of information in seconds, uncovering patterns and connections completely invisible to the human eye.

Giving Your Factory a Brain

At its core, AI learns from data. Instead of being programmed for every possible scenario, it studies past information, like old machine performance or quality control logs, to figure out how things are supposed to work. This ability to learn is what allows it to make intelligent predictions and sharp recommendations.

Two key technologies make this happen:

- Machine Learning: This is like teaching a computer through experience. You feed it thousands of examples, and it begins to recognise patterns on its own. By analysing sensor data from a critical machine, for instance, it can learn the subtle vibrations and temperature shifts that signal an impending breakdown.

- Computer Vision: This gives machines the ability to “see” and understand their surroundings. A camera on your assembly line, powered by computer vision, can inspect thousands of parts a minute, catching microscopic cracks or slight colour variations with perfect consistency.

By bringing these concepts together, AI shifts your whole operation from being reactive, fixing problems after they happen, to being proactive, where you stop them from ever occurring.

This means you can see a critical machine needs maintenance before it fails and shuts down the whole line. It means you can guarantee every single product leaving your factory meets the highest quality standards. The ultimate goal is to build a more resilient, efficient, and intelligent manufacturing environment.

The Core Applications of AI in Manufacturing

To really get a feel for how AI is changing manufacturing, it’s best to look at where it’s making the biggest difference on the ground. This isn’t about one single, magical change. It’s a collection of smart, practical applications that work together to make the entire factory run better, from the supply dock to the assembly line.

Let’s walk through the most powerful ways AI is being used on the factory floor today. These applications, from sophisticated robotics like BMW’s deployment of AI robots for assembly efficiency to intelligent maintenance scheduling, are solving real, everyday problems that manufacturers have dealt with for decades.

The table below breaks down the most common AI applications, the core problems they address, and the tangible benefits they deliver.

Core AI Applications in Manufacturing

| AI Application | Common Problem Solved | Key Business Benefit |

|---|---|---|

| Predictive Maintenance | Unplanned equipment downtime and inefficient, scheduled servicing. | Reduced downtime, lower maintenance costs, and extended asset life. |

| AI-Powered Quality Control | Human error in defect detection, inconsistent quality, and product recalls. | Higher product quality, less material waste, and improved brand reputation. |

| Supply Chain Optimisation | Inventory shortages or overages, shipping delays, and demand forecasting errors. | Lower inventory costs, improved on-time delivery, and a more resilient supply chain. |

| Process Optimisation | Hidden inefficiencies in production workflows, high energy consumption, and bottlenecks. | Increased throughput, lower operational costs, and improved overall equipment effectiveness (OEE). |

Each of these applications represents a shift from a reactive, “wait-and-see” approach to a proactive, data-driven one, fundamentally changing how decisions are made.

1. Predictive Maintenance: Keeping Machines Running

Imagine your most critical piece of machinery having a personal doctor, constantly checking its pulse and vital signs. That’s essentially what predictive maintenance does. Instead of waiting for a machine to break down and bring production to a grinding halt, AI can forecast a failure before it happens.

Traditionally, maintenance has been either reactive (fixing things after they break) or preventative (servicing machines on a fixed schedule, whether they need it or not). Both are flawed. Reactive maintenance leads to expensive, unplanned downtime. Scheduled maintenance often means wasting time and money servicing perfectly healthy equipment.

AI changes the game entirely. It uses data from sensors monitoring vibration, heat, and sound to learn the unique operational “heartbeat” of each machine. It can then detect the tiniest deviations from this baseline. These are subtle changes that signal a problem is on the horizon, long before a human operator would notice anything is wrong.

This allows you to schedule repairs during planned downtime, order parts in advance, and avoid those catastrophic failures that cripple your entire operation. It’s the difference between a routine check-up and a trip to the emergency room.

2. AI-Powered Quality Control

No matter how skilled your team is, inspecting thousands of products for microscopic defects is a gruelling, repetitive job. The human eye gets tired, and tiny imperfections can easily slip through. This is where AI-powered quality control steps in, acting like a tireless inspector with superhuman vision.

Using high-resolution cameras, an AI system can scan every single item coming off the production line in a fraction of a second. It compares each product against a “golden standard” digital model, looking for microscopic cracks, colour inconsistencies, or assembly errors that are nearly impossible to spot manually.

If it finds a defect, it can instantly flag the item and even trace the issue back to a specific point in the production line that might be causing it. This not only ensures faulty products never reach the customer but also helps you fix the root cause of quality issues much faster. The result is less waste, fewer returns, and a stronger reputation for quality.

3. Optimising the Supply Chain

A manufacturing operation is only as strong as its supply chain. Delays in raw materials or distribution snags can create massive bottlenecks and stall production. AI helps untangle this complex web of logistics, making your entire supply chain smarter and more responsive.

Think of it as a smart GPS for your materials. Instead of just following a set route, AI can analyse real-time data on shipping traffic, weather patterns, and even supplier production schedules to find the most efficient path. It can predict customer demand with far greater accuracy, helping you maintain the perfect level of inventory, not too much, and not too little.

This means avoiding costly stock shortages that pause production while also slashing the expense of storing excess materials. The system can even automate reordering when stock is low and adjust delivery schedules based on real-time events, creating a smooth, uninterrupted flow from supplier to factory to customer.

4. Fine-Tuning Production Processes

Beyond individual tasks, AI can take a holistic view of the entire manufacturing workflow to find hidden opportunities for improvement. This is known as process optimisation. An AI system acts like an experienced efficiency expert who can analyse millions of data points at once to uncover patterns a human would miss.

It monitors everything from machine settings and energy consumption to the speed of the assembly line. By identifying subtle correlations, it can suggest small adjustments that lead to big gains. For instance, it might discover that slightly changing the temperature during one stage of the process reduces energy use by 5% without impacting quality at all.

These are the kinds of optimisations that are almost impossible to find through manual analysis. Over time, these continuous, small improvements add up, leading to significantly lower operational costs and higher output. It’s all about making your existing processes work smarter, not just harder. Our detailed guide on robotic process automation delves deeper into how to automate these kinds of business workflows.

For Australia’s manufacturing sector, this isn’t a distant future. A staggering 75% of local manufacturers expect AI to be one of their top three contributors to operational margins by 2026. The early adopters are already reaping the rewards, with nearly 40% reporting measurable gains from AI-driven quality control and planning, which helps slash defects and make better use of resources.

How to Build Your Smart Factory

So, you’re ready to bring the power of AI into your own operations? The idea of building a “smart factory” can feel overwhelming, like you need to rip out everything and start from scratch. But the reality is far more practical. It’s about taking deliberate, logical steps to build intelligence into your existing processes, starting with the one asset you already have in abundance: data.

Think of it like building a house. You wouldn’t start putting up walls without a solid foundation. In the world of AI in manufacturing, your data is that foundation. Without a clean, organised, and accessible supply of it, everything else you try to build on top will be unstable.

Start with a Strong Data Foundation

AI learns from information, much like a person learns from experience. The quality of the insights it generates is directly tied to the quality of the data it’s fed. To get a complete picture, you’ll need to pull information from various sources across your entire operation.

This typically includes:

- Sensor Data: Information flowing from your machines about temperature, vibration, speed, and other operational metrics. This is the lifeblood for applications like predictive maintenance.

- ERP Systems: Data on inventory levels, supply chain movements, and production orders. This gives the AI the broader business context it needs to make sense of the operational data.

- Quality Logs: Records of defects, scrap rates, and inspection results. This is the raw material for training an AI to spot quality issues far better than the human eye can.

Getting this data organised is the crucial first step. A recent study delivered a sobering reality check. Only 21% of Australian manufacturing companies consider themselves fully AI-ready, often because of gaps in their data infrastructure and system integration. For many businesses, this statistic hits close to home, highlighting missed opportunities where disconnected systems inflate costs and limit growth. You can read more about these Australian manufacturing readiness findings to see how you compare.

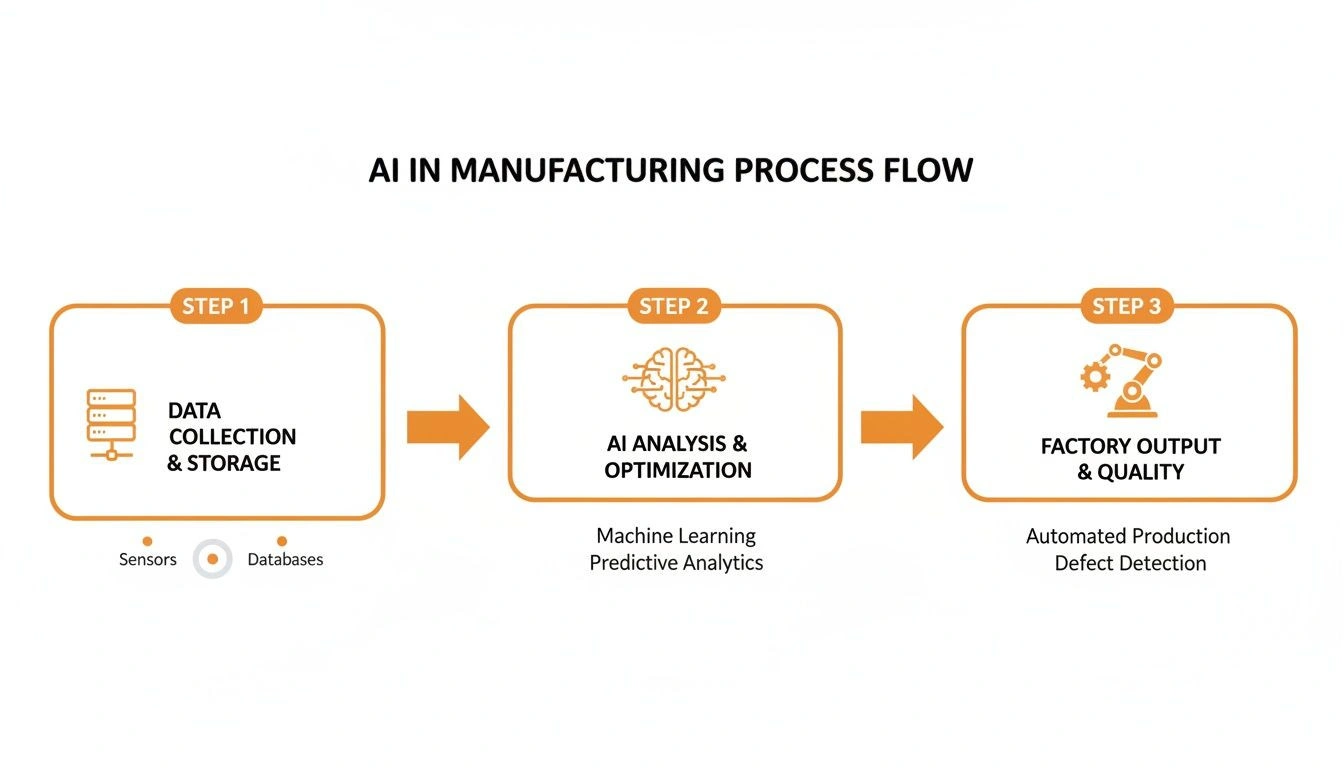

The process flow for AI in manufacturing really is that simple. It moves from raw data to intelligent analysis and, finally, to a better factory output.

As you can see, without high-quality data at the start, the entire AI-driven process falters before it even begins.

Laying the Technology Bricks

Once your data is in order, you can start putting the core technology in place. Again, this doesn’t have to be overwhelmingly complex. Think of it as assembling a toolkit where each tool has a very specific job.

Your toolkit will generally include:

- Cloud Platforms: These provide the raw computing power needed to process massive amounts of data and run complex AI models. It’s like renting a supercomputer instead of having to buy and maintain one yourself.

- IoT Sensors: These are the “eyes and ears” on your factory floor, collecting the real-time data that feeds your AI. Many modern machines already have them built-in.

- AI Models: These are the specialised algorithms that do the actual “thinking.” You might have one model dedicated to predicting machine failures and another one trained to spot product defects on the line.

It all comes down to choosing the right tools for the job. You can get expert help selecting and implementing the right technology stack from experienced AI consultants who genuinely understand the manufacturing landscape.

Prove the Value with a Pilot Project

The single biggest mistake you can make is trying to do everything at once. A much smarter approach is to start small with a tightly focused pilot project. Pick one specific, high-impact problem and use AI to solve it.

A pilot project is your proof of concept. Its goal is to deliver a clear, measurable win that demonstrates the value of AI to everyone in the organisation, from the shop floor to the executive suite.

For instance, you could focus on reducing scrap on a single production line that has a known, persistent quality issue. By collecting data from that line and using an AI model to identify the root cause of the defects, you can show a direct, undeniable return on investment. Efficiently managing this data is critical, and a solid grasp of automated data processing can make a massive difference in the success of your pilot.

Scaling Your Success Across the Factory

Once your pilot project delivers results, you have a blueprint for success. You’ve not only proven the technology works, but you’ve also shown a clear financial benefit and built momentum within your team. Now, you can start scaling that success.

This final step involves taking the lessons learned from your pilot and applying them to other areas of the business. You might roll out predictive maintenance to other critical machines or expand your new AI-powered quality control to more production lines.

This methodical, step-by-step approach turns the daunting task of building a smart factory into a manageable journey. It’s not a single, giant leap, but a series of well-planned steps, with each one building on the success of the last.

Integrating AI with Your Existing Factory Systems

One of the biggest hurdles for any manufacturer considering AI is the fear of disruption. You’ve spent years, maybe decades, building and refining the systems that run your business. Your Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES) are the operational backbone. The idea of tearing all that out is a non-starter.

Thankfully, that’s not how it works.

Modern AI isn’t a replacement for your core systems. It’s an intelligence layer that sits on top. Think of your existing infrastructure as the solid foundation of a house. AI is the smart home technology you install to make everything run better, using the structure that’s already there. The goal is to create a seamless bridge, letting data flow from your trusted systems to the new AI engine and back again.

This connection is what breathes new life into your historical data. The AI taps into the wealth of information already sitting in your ERP and MES, learns from it, and then pushes actionable insights back into the very workflows your team uses every single day.

Making the Connection Feel Natural

The real magic happens when you break down the data silos. A successful AI implementation depends on creating a unified system where your ERP, MES, and new AI tools are all speaking the same language. This creates a single source of truth for the entire operation.

When done right, this connected approach is what unlocks the true potential of AI in manufacturing. Of course, getting different systems to work in concert often requires specialised systems integration services to ensure every component communicates flawlessly.

Imagine an AI model predicts an imminent failure on a critical machine. In a fully integrated environment, that insight doesn’t just appear on a dashboard. It automatically triggers a maintenance work order in your MES, assigns it to a technician, and even checks inventory for the necessary spare parts in your ERP.

Your team isn’t forced to jump between different screens or manually transfer information. The intelligence is simply embedded into their existing routine, making their jobs easier, not more complex.

The Power of a Flexible, Mix-and-Match Approach

A huge benefit of today’s integration strategies is that you aren’t locked into a single, monolithic solution. You have the freedom to select the best tool for each specific job, creating a customised tech stack that perfectly matches your factory’s unique challenges.

This vendor-agnostic philosophy gives you a massive advantage:

- No Vendor Lock-In: You’re not stuck with one provider’s ecosystem. As better or more specialised tools emerge, you have the agility to adopt them.

- Smarter Investment: You can direct your budget toward solving your most pressing problems first, rather than paying for a bloated, all-in-one platform with features you’ll never use.

- Perfectly Tailored Systems: You get to build a solution that is meticulously aligned with your specific production lines, supply chain, and business goals.

The real objective is to create a digital ecosystem where every piece of technology, old and new, works together. This collaboration is what transforms a traditional factory into a smart, agile, and data-driven operation.

For any business embarking on this journey, understanding the core principles of system integrations is the essential first step toward building a truly connected and intelligent factory.

A Gradual and Intelligent Transition

Bringing AI into your factory shouldn’t feel like a sudden, jarring overhaul. It’s a progressive journey of layering intelligence onto the strong foundation you’ve already built. With a clear strategy, you can ensure a smooth transition that minimises risk while maximising your return.

This measured approach means you can introduce new capabilities at a comfortable pace. Start small. Connect an AI tool to a single data source to solve one high-impact problem. Once you see the results and your team gains confidence, you can expand the connections and tackle the next challenge. This makes the entire process manageable, effective, and built for long-term success.

Leading Your Team Through the AI Transition

New technology is only ever half the picture. The other, arguably more important half, is your people. A successful AI in manufacturing project is as much about managing a cultural shift as it is about installing new software. Getting this right means focusing on the human element from day one.

It all comes down to genuine buy-in, from the operators on the factory floor right up to the executive team. This begins with clear, honest communication about why the change is happening. Forget the narrative about robots taking jobs. The real story is about introducing smart tools to help people do their jobs better, safer, and with far less frustration.

Frame AI as a helpful co-pilot. For instance, it can take over the mind-numbing task of watching parts for tiny defects, freeing up a skilled technician to solve more complex production puzzles. This simple shift in perspective is often the key to turning anxiety into advocacy.

Communicating the ‘Why’ Clearly

Before a single piece of tech is rolled out, you need a compelling story. People have to understand the purpose behind this shift and, crucially, how it makes their work life better. Vague statements about “improving efficiency” just won’t land. You need to be specific and relatable.

So, instead of talking about data, talk about outcomes. Show your team how a predictive maintenance tool means fewer surprise breakdowns and fewer stressful, late-night repairs. Explain how a smarter supply chain system means they won’t have to scramble for missing parts again.

The goal is to connect the dots between the technology and a better workday. When your team sees AI as a solution to their daily headaches, they will become your biggest champions.

This kind of clear, transparent communication builds a foundation of trust, which is absolutely essential for navigating any significant operational change.

Building Skills for the Future

Fear of the unknown is a powerful and natural reaction. The most effective way to counter it is with education and training. Investing in upskilling your workforce isn’t just a good idea. It’s a non-negotiable part of any AI transition. It sends a clear message: you’re investing in their future, not planning to replace them.

Your training program needs to be practical and hands-on, focusing on how people will work alongside these new systems. This could include:

- Operator Training: Teaching staff how to properly interpret dashboards and alerts from an AI monitoring system.

- Maintenance Skills: Upskilling technicians so they can service and collaborate with AI-driven machinery.

- Data Literacy: Helping supervisors understand the insights AI provides so they can make sharper, more informed decisions on the floor.

This proactive approach does more than just prepare your team, it empowers them. It gives them the confidence to embrace new tools and take ownership of the new processes. When your team feels prepared and valued, they’re far more likely to see the full potential of AI. If you need help structuring this transition, working with experienced AI consultants can provide a clear roadmap for both your technology and your team.

How to Choose the Right AI Partner

Deciding to integrate AI into your manufacturing operations is a significant move. But just as critical is finding the right company to guide you through it. The world of AI vendors is crowded and can be confusing, so the goal is to find a genuine partner focused on solving your specific business problems, not just selling you a piece of software.

Think of it like hiring a specialist for a custom renovation. You wouldn’t bring in a plumber to rewire your entire factory. You need an expert who understands the unique environment and its distinct challenges, in this case, the factory floor.

Look for Deep Manufacturing Know-How

Your first filter should be straightforward: does this vendor actually understand manufacturing? A partner with real-world experience in your sector will already speak your language. They’ll get the nuances of Overall Equipment Effectiveness (OEE), the constant pressure on supply chains, and the common bottlenecks that stall production.

A good sign is when they start by asking about your workflows and production lines, long before they even mention a solution. Their interest should be in your operational headaches, not just their own tech stack. This kind of deep industry knowledge is what separates a true partner from a generic software salesperson.

Prioritise Custom Solutions Over Rigid Products

Be cautious of any vendor pushing a single, one-size-fits-all product. Every factory is different, with its own machinery, processes, and unique set of problems. The right partner will offer a flexible approach, ready to build a solution that’s shaped around your specific needs.

A true partnership is collaborative. You’re looking for a team that will work with you to co-create a solution that delivers measurable, real-world results and tackles your most pressing business challenges.

This tailored approach ensures you aren’t paying for features you’ll never use or trying to shoehorn your operations into a rigid system that simply wasn’t designed for them.

Demand Comprehensive, Long-Term Support

Finally, a great partner doesn’t vanish once the system goes live. They stick around to offer comprehensive support, from training your team to providing ongoing maintenance and optimisation. They should be invested in your long-term success, helping you adapt the AI as your business evolves.

Australia’s manufacturing sector is increasingly embracing AI, reflecting a national trend where 68% of companies plan to embed it into their digital products by 2026. This signals a shift from small-scale pilots to full operational rollouts, with AI managing everything from inventory forecasting to quality control. Early projects have shown remarkable results, sometimes reducing equipment downtime by up to 50%. For businesses seeking a customised path, experienced AI consultants can bridge the gap from concept to reality. You can read more about Australia’s AI adoption trends and opportunities to see the bigger picture.

Common Questions About AI in Manufacturing

Jumping into any new technology brings up questions. When it comes to something with the potential of AI in manufacturing, it’s smart to want clear, straightforward answers before you commit. We’ve tackled some of the most common questions we hear from business leaders, breaking them down into practical terms.

Is AI Too Expensive for a Medium-Sized Business?

Not necessarily. The trick is to start small and think strategically. You don’t need a massive, factory-wide overhaul right out of the gate. A much smarter approach is to begin with a focused pilot project targeting a single, high-impact problem, like reducing scrap from one particularly wasteful production line.

A successful pilot can deliver a clear and often surprisingly quick return on investment. That initial win builds the business case and momentum you need to fund the next project, turning your AI adoption into a scalable, financially sensible upgrade rather than a huge upfront cost.

Will AI Replace Jobs on Our Factory Floor?

This is a common concern, but the goal of AI in manufacturing isn’t to replace people, it’s to work alongside them. Think of it as a powerful new tool for your team, boosting their skills by taking over the repetitive, tedious, or even dangerous tasks.

For example, an AI vision system can perform thousands of mind-numbing quality checks with unwavering consistency. This doesn’t make your skilled inspectors redundant. It frees them up to apply their expertise to more valuable work, like refining processes, fine-tuning complex machinery, or solving nuanced production issues that require human ingenuity.

How Much Data Do We Need to Get Started?

You probably have more than enough data to begin right now. Many manufacturers are sitting on a goldmine of historical information in their existing systems, like an ERP or a Manufacturing Execution System (MES).

You likely already have valuable data sources ready to go, including:

- Production logs from previous runs

- Quality control records detailing defects and their causes

- Maintenance reports on equipment service history

A good implementation partner can help you assess the data you already have and identify the perfect, low-risk starting point for a first project.

What Is the Biggest Challenge in an AI Project?

It’s rarely the technology itself. More often than not, the biggest hurdles are tied to people and processes. The two most critical first steps are getting genuine buy-in from your team and ensuring your data is clean, organised, and ready for use.

The best way to build momentum and overcome any internal resistance is to start with a clear business problem that everyone agrees needs solving. When you deliver an early, measurable win, you demonstrate the value of AI in a tangible way that gets the whole team on board.

At Osher Digital, we specialise in turning these challenges into opportunities. If you’re ready to explore what a practical, results-driven AI strategy could look like for your business, our team of expert AI consultants is here to help you build a clear roadmap to success.

Jump to a section

Ready to streamline your operations?

Get in touch for a free consultation to see how we can streamline your operations and increase your productivity.