Top Business Process Improvement Examples to Boost Operations in 2025

Discover effective business process improvement examples to streamline operations and drive growth in 2025. Learn key strategies today!

‘Business process improvement’ (BPI) is more than just a corporate catchphrase; it’s the engine of sustainable growth and operational excellence. Many organisations struggle to move from theoretical knowledge to practical application. The key isn’t just knowing what BPI is, but seeing how it’s successfully implemented in real-world scenarios.

This article cuts through the noise to provide a strategic breakdown of tangible business process improvement examples. We will explore eight detailed case studies, analysing the challenges, the specific process changes or automations applied, and the measurable outcomes achieved. Each example is structured to offer not just inspiration, but a replicable blueprint with actionable takeaways you can apply to your own operations. By examining these successes, you can better identify opportunities to drive efficiency, reduce costs, and scale your business effectively.

While this article focuses on practical examples, understanding the underlying frameworks is also crucial. To delve deeper into the methodologies and tools available, consider exploring the various Process Improvement Techniques that form the foundation of these strategies. Let’s examine how leading organisations put these concepts into action.

1. Lean Six Sigma Implementation

Lean Six Sigma is a powerful, data-driven methodology that provides a structured framework for business process improvement. It merges two proven approaches: Lean, which focuses on eliminating waste and non-value-added activities, and Six Sigma, which aims to reduce process variation and defects. The result is a comprehensive strategy that streamlines operations, enhances quality, and boosts profitability.

This dual-focus approach makes it one of the most effective business process improvement examples for organisations striving for operational excellence. For instance, General Electric famously saved over $12 billion in five years by embedding Six Sigma principles into its culture. Similarly, Amazon leverages Lean Six Sigma in its fulfilment centres to minimise picking and packing errors, directly improving customer satisfaction and operational speed.

Strategic Analysis & Application

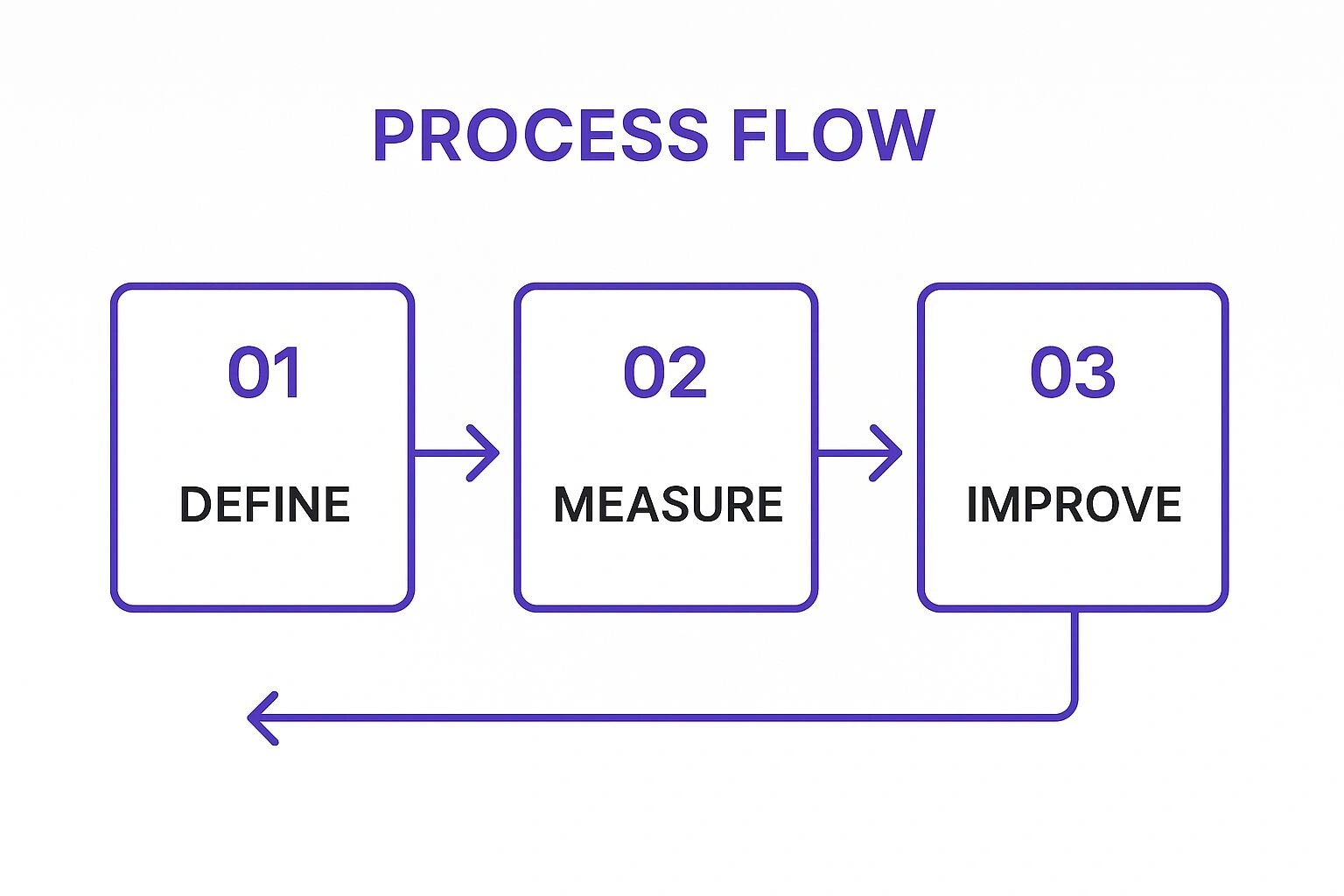

The core of Lean Six Sigma is a systematic, five-phase cycle known as DMAIC (Define, Measure, Analyse, Improve, Control). This methodical approach ensures that improvements are based on verifiable data, not assumptions. It forces teams to precisely define the problem, measure current performance, analyse root causes, implement targeted solutions, and establish controls to sustain the gains.

Key Strategic Insight: Lean Six Sigma succeeds because it moves problem-solving from anecdotal feedback to empirical analysis. By focusing on measurable defects and process waste, it provides a clear, objective path to enhancing value for both the company and the customer.

This methodology is particularly effective for complex, high-volume processes where even minor inefficiencies or defects can lead to significant financial losses or customer dissatisfaction. It is ideal for manufacturing, logistics, finance, and healthcare sectors.

The following infographic illustrates a simplified flow, showing the foundational stages that drive a Lean Six Sigma project forward.

This sequence highlights how each phase builds upon the last, creating a logical progression from problem identification to sustainable improvement.

2. Business Process Automation (BPA)

Business Process Automation (BPA) is the strategic use of technology to automate repetitive, rule-based business processes. Its primary goal is to improve efficiency, reduce human error, and free up valuable employee time for higher-value, strategic activities. BPA involves identifying manual tasks, such as data entry or report generation, and implementing software solutions like Robotic Process Automation (RPA) or workflow automation tools to handle them automatically.

This technology-driven approach is one of the most impactful business process improvement examples for modern organisations. For instance, JPMorgan Chase automated legal document review, saving an estimated 360,000 hours of work annually. Similarly, Walmart leverages BPA to automate inventory management across its thousands of stores, ensuring product availability while minimising carrying costs. These cases show how BPA directly translates into significant operational gains and resource optimisation.

Strategic Analysis & Application

The effectiveness of BPA lies in its ability to execute tasks with perfect accuracy and speed, 24/7. To apply it successfully, organisations must first thoroughly map their current processes to identify bottlenecks and suitable candidates for automation. The most common targets are high-volume, low-complexity tasks that are prone to human error and consume significant manual effort. Tools like UiPath, Blue Prism, and Microsoft Power Automate are then configured to mimic human actions within existing IT systems.

Key Strategic Insight: BPA delivers its greatest value not just by replacing manual labour, but by creating a more agile and scalable operational foundation. By automating core processes, organisations can handle increased workloads without a proportional increase in headcount, enabling sustainable growth.

This method is highly effective for functions heavily reliant on routine tasks, such as finance (invoice processing), HR (employee onboarding), and customer service (handling standard inquiries). A gradual rollout, starting with a pilot project, allows for refinement and helps manage the organisational change required for a successful implementation.

3. Agile Methodology Implementation

Agile is a flexible, iterative approach to managing projects and developing solutions that prioritises collaboration, customer feedback, and rapid adaptation to change. Originally created for software development, its principles are now a cornerstone of modern business process improvement examples, helping organisations across all sectors enhance responsiveness and deliver value faster. It breaks large projects into small, manageable increments called “sprints,” enabling continuous improvement and realignment with stakeholder needs.

This people-centric methodology empowers teams to respond swiftly to market shifts. For example, financial institutions like Capital One have adopted Agile to accelerate their digital transformation initiatives, launching new customer-facing products much faster than traditional waterfall methods would allow. Similarly, Spotify revolutionised its product development by organising teams into autonomous “squads” and “tribes,” fostering a culture of innovation and speed that is now emulated worldwide.

Strategic Analysis & Application

The core of Agile lies in its iterative cycles and commitment to continuous feedback. Frameworks like Scrum and Kanban provide the structure for these cycles, focusing on delivering functional increments of a project in short, time-boxed periods. This approach contrasts sharply with traditional “big bang” project delivery, minimising risk by allowing for regular course correction based on real-world testing and stakeholder input.

Key Strategic Insight: Agile succeeds by shifting the focus from rigid, long-term plans to adaptive, value-driven execution. It champions a culture of transparency and shared ownership, ensuring that the final output is precisely aligned with current business needs, not outdated assumptions.

Agile is particularly effective for projects where requirements are expected to evolve or where the final solution is not fully understood at the outset. It thrives in dynamic environments such as technology, marketing, and product development. For organisations looking to deepen their Agile adoption, exploring frameworks like the Agile Fluency Model can provide a clear roadmap for maturity.

4. Customer Journey Mapping and Optimisation

Customer Journey Mapping is a strategic process used to visualise every interaction a customer has with an organisation. By charting all touchpoints, from initial awareness to post-purchase support, businesses can pinpoint friction points and opportunities for enhancement. This method directly links internal processes to customer satisfaction, making it a powerful tool for aligning operations with customer needs and expectations.

This customer-centric approach is one of the most impactful business process improvement examples because it shifts the focus from internal efficiency to external experience. Starbucks, for instance, used journey mapping to identify the need for its mobile ordering and loyalty programs. Similarly, Airbnb redesigned its entire booking process after mapping the user experience and identifying significant friction points for both guests and hosts.

Strategic Analysis & Application

The effectiveness of journey mapping comes from its ability to foster empathy and provide a holistic view of the customer experience. The process involves gathering data from multiple sources, including surveys, interviews, and analytics, to create a detailed map of customer thoughts, feelings, and actions at each stage. This forces cross-functional teams, from marketing to product development and support, to collaborate and see the business through the customer’s eyes.

Key Strategic Insight: Customer Journey Mapping turns abstract customer feedback into a concrete, actionable blueprint. By visualising pain points and “moments of truth,” it allows organisations to prioritise process changes that deliver the greatest impact on customer loyalty and lifetime value.

This methodology is particularly valuable for service-based industries or businesses with complex, multi-channel customer interactions, such as retail, finance, and telecommunications. For example, USAA successfully optimised its insurance claims process by mapping the customer’s journey, leading to a 40% improvement in efficiency and a significant boost in customer satisfaction during a stressful time for the policyholder.

5. Value Stream Mapping

Value Stream Mapping (VSM) is a lean management technique used to visualise, analyse, and improve all the steps in a product or service delivery process. It involves creating a detailed flowchart that documents every action required from receiving a customer request to final delivery. By mapping both value-added activities and non-value-added waste, organisations gain a holistic view of their material and information flows.

This visualisation makes VSM a standout among business process improvement examples for its ability to expose hidden inefficiencies. Toyota, a pioneer of the technique, famously used it to reduce automotive assembly time by 25%. Similarly, Virginia Mason Medical Center applied VSM to its clinical processes and successfully reduced patient wait times by a remarkable 44%, demonstrating its versatility outside of manufacturing.

Strategic Analysis & Application

The power of VSM lies in its two-stage approach: creating a “current state” map and designing a “future state” map. The current state map provides a baseline by showing the process as it actually operates, identifying bottlenecks, delays, and waste. The future state map then outlines a redesigned, leaner process that eliminates these non-value-added steps, creating a clear roadmap for implementation.

Key Strategic Insight: Value Stream Mapping forces organisations to see their processes through the customer’s eyes. It shifts the focus from optimising individual departments or tasks to improving the end-to-end flow that delivers value, ensuring that all improvement efforts are aligned with customer satisfaction.

This method is particularly powerful for improving complex cross-functional workflows, such as supply chain management, product development, or patient care pathways. By involving employees who perform the work, it fosters collaborative problem-solving and ensures that improvements are practical and sustainable. To get a deeper understanding of this and other similar methods, you can learn more about business process mapping techniques on osher.com.au.

6. Digital Transformation and Cloud Migration

Digital transformation is the comprehensive integration of digital technology into all areas of a business, fundamentally changing how organisations operate and deliver value. This involves migrating legacy systems to cloud platforms, implementing digital workflows, and leveraging data analytics to drive smarter decisions. The goal is to create a more agile, efficient, and customer-centric operation.

This modern approach is one of the most impactful business process improvement examples available today. For instance, Netflix’s transition from a DVD mail service to a cloud-based streaming giant revolutionised the entertainment industry. Similarly, Maersk digitised its global shipping operations, which improved container tracking and operational efficiency by 20%, showcasing the power of a connected digital ecosystem.

Strategic Analysis & Application

Effective digital transformation is not just about adopting new technology; it is about reimagining business processes to leverage that technology’s full potential. The strategy often involves moving infrastructure to scalable cloud platforms like AWS or Microsoft Azure, which reduces capital expenditure on physical servers and enhances data accessibility. This shift enables businesses to automate manual tasks, streamline communication, and gain real-time insights from operational data.

Key Strategic Insight: True digital transformation succeeds when it aligns technology adoption directly with core business objectives. By focusing on solving specific customer or operational problems, it moves beyond a simple IT upgrade to become a fundamental driver of competitive advantage and sustainable growth.

This strategy is particularly effective for organisations burdened by siloed data, inefficient manual workflows, or outdated legacy systems that hinder scalability. It is essential for industries facing rapid market changes, such as retail, finance, logistics, and media. To learn more, explore these digital transformation best practices.

7. Supply Chain Optimisation

Supply chain optimisation is the strategic re-engineering of processes to reduce costs, enhance efficiency, and improve customer service. It involves synchronising the entire network of suppliers, manufacturers, distributors, and retailers to create a seamless flow of goods and information. By improving demand forecasting, minimising lead times, and leveraging technology, companies can gain a significant competitive edge.

This discipline is one of the most impactful business process improvement examples because it directly affects both the cost of goods sold and customer satisfaction. For example, Walmart’s pioneering cross-docking system allows it to move products directly from inbound to outbound trucks, drastically reducing inventory holding costs. Similarly, Zara’s agile supply chain enables a design-to-shelf cycle of just two weeks, allowing it to respond rapidly to changing fashion trends.

Strategic Analysis & Application

Effective supply chain optimisation requires a holistic view, treating the supply chain not as a series of separate steps but as one integrated ecosystem. The goal is to improve visibility and control from end to end. This involves implementing robust inventory management, refining demand forecasting with data analytics, and building strong collaborative relationships with key suppliers to mitigate risks and bottlenecks.

Key Strategic Insight: True supply chain optimisation moves beyond simple cost-cutting to create value. It focuses on building a resilient, agile, and responsive network that can adapt to market disruptions and evolving customer expectations, turning operational efficiency into a powerful competitive advantage.

This approach is crucial for businesses in retail, manufacturing, and e-commerce, where efficient logistics are fundamental to profitability and market share. As companies look for ways to streamline their operations, they can explore strategies to improve operational efficiency. Optimising the supply chain is a foundational step in that journey.

8. Employee Onboarding Process Redesign

An employee onboarding process redesign is a strategic overhaul of how new hires are integrated into an organisation. It moves beyond basic orientation paperwork to create a structured, engaging, and supportive journey that accelerates a new employee’s time to full productivity. The goal is to improve talent retention, enhance the employee experience, and align newcomers with the company’s culture and performance expectations from day one.

This is a critical business process improvement example because a poor onboarding experience directly correlates with high employee turnover. Companies like Google have famously refined this process, leading to a 25% improvement in new hire performance. Similarly, Microsoft’s redesigned digital onboarding platform reduced administrative processing time by 65%, allowing HR teams and managers to focus on more value-adding integration activities.

Strategic Analysis & Application

Effective onboarding redesign focuses on streamlining workflows and personalising the experience. This involves automating paperwork through HR software, creating role-specific learning paths, and implementing mentorship or buddy systems. The process should begin before the employee’s first day and extend through their first 90 days, ensuring they feel supported as they navigate their new role and organisational culture.

Key Strategic Insight: Onboarding is not an administrative checklist; it is the first and most critical touchpoint in the employee lifecycle. A successful redesign transforms it from a procedural formality into a strategic tool for talent retention and cultural assimilation, creating a foundation for long-term employee success and engagement.

This process improvement is particularly vital for companies experiencing rapid growth, high turnover, or those with complex roles that require significant ramp-up time. It is a foundational element for building a strong, cohesive, and high-performing workforce. Redesigning onboarding provides a clear pathway to maximising the return on investment for every new hire.

8 Key Business Process Improvement Examples Comparison

| Methodology / Approach | Implementation Complexity | Resource Requirements | Expected Outcomes | Ideal Use Cases | Key Advantages |

|---|---|---|---|---|---|

| Lean Six Sigma Implementation | High – requires extensive training and certification; complex for simple processes | Significant training, certification, data analysis tools | Reduced costs (15-25%), improved quality, process standardization | Process improvement, quality control, manufacturing and services | Data-driven decisions, waste elimination, ROI measurement |

| Business Process Automation (BPA) | Moderate to High – technical setup and systems integration needed | High upfront technology investment, ongoing maintenance | 60-90% reduction in routine task time, error elimination, 24/7 processing | Repetitive, rule-based tasks, document processing, compliance | Scalability, error reduction, improved compliance |

| Agile Methodology Implementation | Moderate – cultural change and ongoing collaboration needed | Investment in training and coaching, collaboration tools | Faster time-to-market, increased customer satisfaction, adaptability | Software development, project management, dynamic business environments | Flexibility, stakeholder feedback, transparency |

| Customer Journey Mapping & Optimization | Moderate – time-intensive data gathering and cross-department coordination | Cross-functional teams, customer data, mapping software | Improved customer satisfaction, loyalty, reduced churn, process alignment | Customer experience improvement, service design, marketing | Holistic customer insight, identifies bottlenecks, enhances collaboration |

| Value Stream Mapping | Moderate – requires cross-team participation and detailed analysis | Time to map processes, involvement of frontline workers | Identifies waste, reduces cycle time, improves flow and communication | Lean manufacturing, process optimization, supply chain | Visualizes entire process, low cost, clear waste identification |

| Digital Transformation & Cloud Migration | High – complex and resource intensive | Significant investment in technology, training, and change management | Improved efficiency, scalability, remote access, real-time insights | IT modernization, scalability, innovation, remote workforce enablement | Enables innovation, cost reduction on infrastructure, enhanced analytics |

| Supply Chain Optimization | High – complex coordination and technology integration | High coordination effort, data analytics tools, supplier collaboration | Cost reduction (10-20%), improved service levels, inventory reduction | Logistics, inventory management, supplier coordination | Increases resilience, improves cash flow, enhances service |

| Employee Onboarding Process Redesign | Moderate – requires customization and cross-department collaboration | HR resources, digital tools, training content development | Faster productivity, higher retention, enhanced engagement | HR process improvement, new hire integration | Consistent onboarding, reduces admin burden, improves retention |

Turning Insights into Action: Your Next Steps in Process Improvement

The diverse business process improvement examples we’ve explored, from Lean Six Sigma implementation to comprehensive digital transformation, reveal a powerful, unifying thread. True advancement isn’t about isolated fixes or simply adopting new software; it’s about embedding a culture of continuous, strategic refinement into the very fabric of your organisation.

These case studies demonstrate that success hinges on a commitment to deeply understanding your current state. Whether through Value Stream Mapping to visualise waste or Customer Journey Mapping to pinpoint friction, the most impactful changes are born from rigorous analysis, not guesswork. The common denominator across these victories is a shift from reactive problem-solving to proactive process optimisation.

Synthesising the Core Principles

As you reflect on these examples, several core principles stand out as universally applicable. These are the strategic pillars that support any successful BPI initiative and should guide your own efforts:

- Data-Driven Diagnosis: Gut feelings are fallible. The best BPI initiatives begin with objective data to identify the true bottlenecks, whether it’s cycle times in a supply chain, error rates in employee onboarding, or customer drop-off points in a sales funnel.

- Incremental Momentum: While a complete digital transformation is a valid goal, momentum is often built through smaller, targeted wins. Automating a single, high-volume administrative task can free up resources and build the business case for more ambitious projects.

- Human-Centric Design: Processes are ultimately executed by and for people. The most sustainable improvements, like those achieved through Agile methods or optimised onboarding, empower employees and delight customers by placing their needs at the centre of the redesign.

- Technology as an Enabler, Not a Panacea: Automation and new software are powerful catalysts, but they are not the strategy itself. Technology should be implemented to serve a clearly defined process goal, such as reducing manual data entry or providing real-time analytics, rather than being adopted for its own sake.

Your Actionable Roadmap to BPI Success

Moving from insight to implementation requires a structured approach. Instead of feeling overwhelmed by the possibilities, focus on a clear, staged plan to begin generating tangible results. Start by identifying a single, high-impact area for improvement. Ask your teams: “What is the one process that, if improved, would have the biggest positive effect on our work or our customers?”

Once you have a target, begin a small-scale discovery phase. Map the current process, gather preliminary data, and talk to the people involved. This initial analysis will provide the clarity needed to select the right BPI methodology and build a compelling case for change. By following this path, you transform the powerful lessons from these business process improvement examples into your own story of operational excellence and competitive advantage.

Ready to move beyond examples and start building a more efficient, automated, and scalable business? Osher Digital specialises in designing and implementing bespoke automation and AI solutions that solve your most complex process challenges. Visit Osher Digital to discover how we can help you turn your BPI vision into a measurable reality.

Jump to a section

Ready to streamline your operations?

Get in touch for a free consultation to see how we can streamline your operations and increase your productivity.