10 Key Business Process Mapping Techniques for 2025

Discover 10 powerful business process mapping techniques to optimise workflows. Master flowcharts, VSM, BPMN, and more for superior efficiency in Australia.

Unlocking Organisational Efficiency: Beyond the Standard Flowchart

Understanding and optimising how your business operates is no longer an option, it’s a necessity for survival and growth. While many are familiar with a basic flowchart, the world of business process mapping is far richer and more powerful. Effective business process mapping techniques provide a visual blueprint of your workflows, revealing hidden inefficiencies, communication breakdowns, and opportunities for significant improvement. This is especially vital when navigating the transition from paper to digital management, as a clear map of current processes prevents simply digitising existing flaws.

This guide moves beyond foundational methods to explore 10 distinct and powerful techniques, from Value Stream Mapping to advanced BPMN and SIPOC diagrams. By mastering these tools, organisations can diagnose operational weaknesses, align cross-functional teams, and build a scalable foundation for automation and strategic growth. Whether you aim to enhance customer experience, streamline internal operations, or prepare for complex systems integration, selecting the right mapping technique is your critical first step. The following analysis provides the actionable detail needed to transform operational chaos into a tangible competitive advantage for your enterprise.

1. Flowchart Mapping: The Universal Language of Process

Flowcharting is arguably the most fundamental of all business process mapping techniques. It provides a clear, visual representation of a process’s sequence using standardised symbols. Rectangles denote specific tasks or actions, diamonds represent decision points, ovals signify the start or end points, and arrows indicate the directional flow of work. This visual simplicity makes it an exceptionally accessible tool, serving as a common language that team members across different departments, from IT to operations, can easily understand and collaborate on.

When and Why to Use It

Flowcharting is the ideal starting point for nearly any process improvement initiative. Use it when you need to document an existing process for the first time, train new employees, or establish a baseline understanding before a major change. For example, a retail company experiencing inefficiencies in its online order fulfilment process could use a flowchart to map every step, from when a customer places an order to when it is dispatched. This map quickly highlights bottlenecks, such as delays in inventory confirmation or manual data entry into the shipping system.

Key Implementation Steps

- Define Scope: Clearly establish the start and end points of the process you are mapping.

- Identify Participants: Gather insights from everyone directly involved in the process to ensure accuracy.

- Draft the Flow: Use standard symbols to sequence activities, inputs, outputs, and decisions.

- Review and Refine: Validate the drafted flowchart with the process participants to correct any inaccuracies or omissions.

The strength of flowchart mapping lies in its universal recognition and ease of use, making it an indispensable technique for organisations aiming to visualise workflows and foster collaborative problem solving.

2. Value Stream Mapping (VSM)

Originating from lean manufacturing principles popularised by Toyota, Value Stream Mapping (VSM) is one of the more strategic business process mapping techniques. It goes beyond a simple workflow diagram by visualising the entire flow of materials and information required to bring a product or service to a customer. A VSM analysis meticulously documents every step, distinguishing between value-added activities (what the customer pays for) and non-value-added activities (waste). This dual focus on material and information flow provides a holistic view of the process, from raw material to final delivery.

When and Why to Use It

VSM is exceptionally powerful when the primary goal is to drastically reduce process cycle times and eliminate waste. It is ideal for complex, multi-stage processes common in manufacturing, supply chain, and software development. For instance, a fast-fashion retailer like Zara could use VSM to map its entire design-to-shelf process. By timing each stage and measuring inventory levels, it can identify bottlenecks, such as delays in fabric sourcing or lengthy quality assurance checks, and redesign the flow to get products into stores faster, a key competitive advantage.

Key Implementation Steps

- Select a Product Family: Focus your efforts on a single product or service family to maintain clarity.

- Create the Current State Map: Walk the actual process (“gemba walk”) to collect real data on timings, inventory, and personnel, then draw the map with standard VSM symbols.

- Identify Waste: Analyse the current state map to pinpoint the seven forms of waste (e.g., waiting, overproduction, defects).

- Design the Future State Map: Develop an ideal, lean process map that eliminates waste and improves flow, setting a target for implementation within 6-12 months.

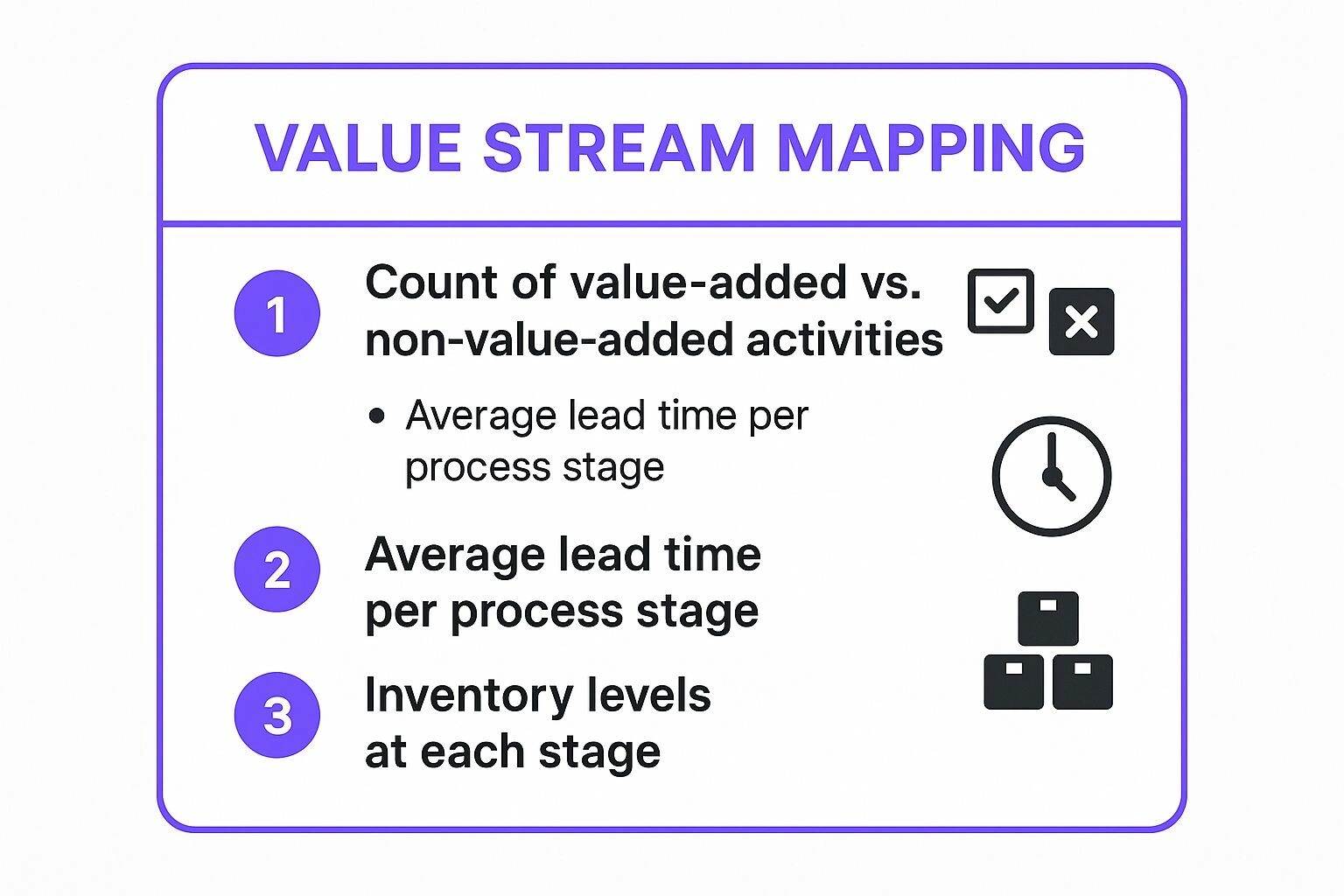

The following infographic highlights key metrics typically captured during a VSM analysis to identify waste and opportunities for improvement.

By quantifying these elements, teams can clearly see where non-value-added activities are inflating lead times and costs, guiding the creation of a more efficient future state.

3. Swimlane Diagrams: Clarifying Roles and Handoffs

Swimlane diagrams, also known as cross-functional flowcharts, are a powerful business process mapping technique that organises process steps into distinct channels or “lanes”. Each lane represents a different role, department, or even system responsible for a set of activities. By visually separating tasks based on ownership, this method excels at showing not just what happens in a process, but who is responsible for each step and, crucially, how handoffs occur between different parties. This clarity is invaluable for untangling complex, cross-functional workflows.

When and Why to Use It

Employ swimlane diagrams when you need to diagnose issues related to delays, miscommunication, or bottlenecks in processes that span multiple teams or departments. It is the perfect tool for analysing accountability and improving collaboration. For instance, a bank mapping its customer onboarding process would use swimlanes for ‘Customer’, ‘Sales Representative’, ‘Credit Analyst’, and ‘Compliance Officer’. The diagram would immediately reveal if delays are caused by slow information transfer from Sales to Credit, or if the Compliance review is holding up account activation, pinpointing exactly where intervention is needed.

Key Implementation Steps

- Identify Participants: Define all the key roles, departments, or systems involved and assign each one a dedicated lane.

- Map the Process Flow: Place the process steps within the lane of the person or group responsible for that action.

- Show Handoffs: Draw arrows connecting tasks between lanes to clearly illustrate when responsibility is transferred.

- Validate and Analyse: Review the diagram with all stakeholders to confirm accuracy and identify redundant steps, delays, or areas of confusion.

The primary strength of swimlane diagrams is their ability to illuminate roles, responsibilities, and interdependencies, making them essential for optimising collaboration and streamlining cross-functional operations.

4. Business Process Model and Notation (BPMN)

Business Process Model and Notation (BPMN) is a standardised graphical representation among business process mapping techniques, governed by the Object Management Group (OMG). It offers a rich, precise visual language designed to bridge the gap between business design and technical implementation. Unlike a simple flowchart, BPMN uses a comprehensive set of symbols to detail events, activities, gateways (decisions), and the flow of messages between different participants or systems. This level of detail makes it an indispensable tool for modelling complex operational workflows with accuracy, ensuring both business stakeholders and IT developers share a common understanding.

When and Why to Use It

BPMN is the preferred method for complex, cross-departmental processes, especially those targeted for automation. Use it when you need to model intricate logic, exceptions, and system interactions with a high degree of precision. For example, a financial institution like Deutsche Bank could use BPMN to map its entire loan origination process. This would involve detailing every step, from the customer application and automated credit checks to manual reviews, approvals, and fund disbursement, including interactions between different software systems and departments. This clarity is vital for regulatory compliance and identifying opportunities for process automation.

Key Implementation Steps

- Select a BPMN Tool: Choose a software platform that supports BPMN 2.0 standards for modelling and potential simulation.

- Start with Core Elements: Begin with basic symbols like tasks, events, and gateways before incorporating more advanced constructs like sub-processes or exception flows.

- Define Pools and Lanes: Use pools to represent separate organisations (e.g., your company and a supplier) and lanes to delineate roles or departments within a pool.

- Validate Rigorously: Ensure the model is validated by both business process owners for accuracy and technical teams for implementation feasibility.

The power of BPMN lies in its ability to capture complexity without ambiguity, making it the gold standard for organisations aiming to automate, optimise, and execute their most critical business processes.

5. Process Flow Analysis

Process Flow Analysis is a systematic and quantitative technique used to examine the sequence of activities within a business process. Unlike more qualitative mapping methods, it focuses intensely on measuring performance metrics like cycle times, wait times, and resource utilisation to identify concrete improvement opportunities. By applying principles from industrial engineering and methodologies like Six Sigma, this approach moves beyond simple visualisation to provide hard data on process efficiency, throughput, and bottlenecks. It’s one of the more analytical business process mapping techniques for optimising performance.

When and Why to Use It

This technique is essential when the goal is to improve measurable outcomes like speed, cost, or output. It is particularly effective for high volume or mission critical processes where small inefficiencies have a large cumulative impact. For example, a hospital emergency department could use Process Flow Analysis to track patient wait times at each stage, from triage to discharge, identifying exactly where delays occur and how to reallocate resources to improve patient throughput. Similarly, a software development team can analyse its pipeline to reduce lead time from code commit to deployment.

Key Implementation Steps

- Establish Baselines: Before making changes, collect detailed performance data on the current process to create a benchmark.

- Gather Data: Use multiple measurement periods, including both average and peak times, to ensure the data is accurate and representative.

- Analyse the Flow: Identify bottlenecks, redundant steps, and areas of underutilisation by examining the collected metrics.

- Model and Implement Changes: Use the data to model potential improvements and implement changes, then measure again to validate their impact.

Process Flow Analysis provides the empirical evidence needed to justify changes and precisely measure their success, making it invaluable for data-driven organisations. For those looking to delve deeper, a structured business process analysis template can provide a solid foundation for your efforts.

6. Customer Journey Mapping: Visualising the Customer’s Experience

Customer Journey Mapping shifts the focus from internal operations to the customer’s perspective. It is one of the most powerful business process mapping techniques for understanding and improving the customer experience. This method visually chronicles every interaction a customer has with an organisation, capturing their actions, thoughts, and emotions across various touchpoints. By mapping this journey, businesses can identify critical “moments of truth,” pinpoint sources of frustration, and discover opportunities to create a more seamless and satisfying experience.

When and Why to Use It

This technique is essential when your goal is to enhance customer loyalty, reduce churn, or align internal processes with customer expectations. Use it to understand why customers are abandoning online shopping carts, to improve the patient experience in a hospital, or to design a better onboarding process for a new software service. For example, a telecommunications company might map the journey of a customer reporting a service outage. The map could reveal frustrations caused by long wait times and multiple transfers, pinpointing specific processes that need redesigning to deliver a better service.

Key Implementation Steps

- Create a Persona: Develop a detailed profile of the customer whose journey you are mapping, based on real data and research.

- Identify Touchpoints and Stages: List all the points of interaction (website, app, in-store, call centre) and group them into logical stages (e.g., awareness, consideration, purchase, service).

- Map Actions, Thoughts, and Emotions: For each stage, document what the customer is doing, thinking, and feeling. Use direct customer feedback wherever possible.

- Identify Pain Points and Opportunities: Analyse the map to locate where the experience breaks down and brainstorm improvements.

Customer Journey Mapping provides an invaluable outside-in view, ensuring that process improvement efforts are directly linked to delivering tangible value to the people who matter most: your customers.

7. Unified Modeling Language (UML) Activity Diagrams

Originating from the world of software engineering, the Unified Modeling Language (UML) Activity Diagram is a powerful and standardised notation adapted for business process modeling. It depicts a process as a flow of activities, using specific symbols to represent actions, decisions, parallel paths (forks), and synchronisation points (joins). This structured approach makes it one of the more rigorous business process mapping techniques, especially suited for documenting complex logic, concurrent operations, and system interactions with a high degree of precision. Its formal nature ensures clarity between technical and business teams.

When and Why to Use It

UML Activity Diagrams are ideal when a process involves intricate logic, parallel processing, or requires tight integration between business workflows and IT systems. For example, a financial services company could use a UML diagram to model its loan application process. The diagram would clearly show concurrent activities like credit checks and employment verification happening simultaneously, decision points based on risk scores, and the final convergence to either approve or deny the application. This level of detail is crucial for automating workflows and ensuring regulatory compliance.

Key Implementation Steps

- Identify Activities and Actions: Break down the process into individual, sequential, and concurrent actions.

- Use Partitions (Swimlanes): Organise activities into columns or rows to show which department or system is responsible for each step.

- Map Control Flows: Use arrows to connect activities, incorporating decision nodes (diamonds) for logic branches and fork/join nodes for parallel activities.

- Validate with Stakeholders: Review the model with both business analysts and technical developers to confirm it accurately represents the process logic and system behaviour.

The strength of UML Activity Diagrams lies in their ability to unambiguously model complex workflows, making them invaluable for projects involving system development, automation, and detailed process re-engineering.

8. Detailed Process Maps: Capturing Granular Detail

For processes where precision and compliance are non-negotiable, Detailed Process Maps offer the highest level of granularity. Unlike more high-level diagrams, this business process mapping technique captures every single action, input, output, exception, and resource involved in a workflow. It acts as an exhaustive operational playbook, documenting specific procedures, system interactions, individual responsibilities, and performance metrics for each granular step. This meticulous approach ensures complete clarity and leaves no room for ambiguity.

When and Why to Use It

This method is essential for high-risk, high-impact, or heavily regulated environments. Use it when process errors could lead to severe consequences, such as in financial audits, nuclear power plant operations, or FDA-regulated pharmaceutical manufacturing. For example, a medical facility would use a detailed map for a surgical protocol. This map would specify not just the sequence of actions, but the exact instruments required, the specific anaesthetic dosage calculations, and the precise hand-off procedures between the surgical team, ensuring patient safety and regulatory adherence.

Key Implementation Steps

- Define Scope and Granularity: Determine the precise boundaries of the process and the level of detail required to eliminate operational risks.

- Engage Process Owners: Involve the frontline staff who execute the process daily to capture accurate, real-world steps and exceptions.

- Document Everything: Map all tasks, decisions, data inputs, system triggers, and communication points. Use consistent templates to standardise documentation across different processes.

- Validate and Review: Conduct thorough walkthroughs with all stakeholders to verify the map’s accuracy and establish a cycle for regular reviews and updates.

The power of Detailed Process Maps lies in their comprehensiveness, making them indispensable for ensuring quality, safety, and compliance in critical operations. To dive deeper into creating such comprehensive documentation, you can review some process documentation best practices.

9. Lean Process Mapping: Eliminating Waste for Maximum Value

Lean Process Mapping is one of the most value-focused business process mapping techniques, originating from the principles of the Toyota Production System. It moves beyond simple visualisation to actively identify and eliminate “muda” or waste within a process. By categorising every process step as either value-adding, non-value-adding but necessary, or pure waste, this technique provides a clear road map for creating more efficient, customer-centric workflows. It’s a strategic tool designed not just to map a process, but to fundamentally improve it by maximising value delivery.

When and Why to Use It

Employ Lean Process Mapping when the primary goal is operational excellence, cost reduction, and enhanced customer value. It is exceptionally effective for mature organisations looking to streamline complex operations or for any business aiming to compete on efficiency. For instance, a hospital could use lean mapping to analyse its patient discharge process. By identifying delays such as waiting for pharmacy prescriptions or final paperwork, the hospital can re-sequence tasks and implement changes to reduce patient wait times, freeing up beds faster and improving the patient experience.

Key Implementation Steps

- Define Customer Value: Clearly articulate what the customer values from the process outcome.

- Walk the Process (Gemba): Go to where the work happens to observe the actual process flow and gather firsthand insights from frontline staff.

- Identify Waste: Use the 8 Wastes framework (Defects, Overproduction, Waiting, Non-Utilised Talent, Transportation, Inventory, Motion, Extra-Processing) to classify each step.

- Design the Future State: Create a new map that eliminates waste and improves flow, focusing on quick wins and long-term improvements.

The power of Lean Process Mapping lies in its relentless focus on efficiency and customer value, making it a critical technique for organisations dedicated to continuous improvement and operational superiority.

10. Six Sigma Process Mapping (SIPOC)

SIPOC (Suppliers, Inputs, Process, Outputs, Customers) is a high level process mapping technique fundamental to the Six Sigma methodology. It provides a structured, bird’s eye view of a process by defining its most essential elements without delving into excessive detail. A SIPOC diagram visually captures the key inputs and outputs of a process, the suppliers providing the inputs, and the customers receiving the outputs. This framework is not designed to show decision points or sequential steps but to clarify process boundaries and scope, making it an excellent starting point for larger improvement initiatives.

When and Why to Use It

SIPOC is most effective at the beginning of a complex process improvement project, particularly those using Six Sigma or Lean methodologies. Use it when you need to quickly get a team on the same page about a process that is poorly defined or has a scope that is not universally understood. For instance, a financial services firm could use a SIPOC diagram to analyse its mortgage approval process. This would clearly identify suppliers (applicants, credit bureaus), inputs (applications, credit reports), the high level process steps, outputs (approval/denial letters), and the customer (the applicant), providing a shared understanding before a more detailed mapping exercise begins.

Key Implementation Steps

- Identify the Process: Start by naming the process and defining its start and end points.

- List Customers and Outputs: Determine who receives the output of the process and what they receive.

- Define Suppliers and Inputs: Work backwards to identify who provides inputs to the process and what those inputs are.

- Validate the Diagram: Review the completed SIPOC diagram with all key stakeholders to ensure it accurately reflects the process from a high level perspective.

Its power lies in establishing a solid foundation and shared language, a critical first step in any structured business process improvement effort.

Business Process Mapping Techniques Comparison

| Technique | Implementation Complexity | Resource Requirements | Expected Outcomes | Ideal Use Cases | Key Advantages |

|---|---|---|---|---|---|

| Flowchart Mapping | Low – easy to learn and create | Low – basic tools and training | Clear visual of process sequence | General process documentation | Universal symbols, easy understanding |

| Value Stream Mapping (VSM) | Medium to High – detailed mapping | High – data collection, training | Waste identification, lead time reduction | Lean manufacturing, process improvement | Highlights value-added vs non-value activities |

| Swimlane Diagrams | Medium – moderate complexity | Medium – organized role input | Clear responsibility and handoffs | Cross-functional processes | Visualizes roles and handoffs clearly |

| BPMN | High – requires specialized training | High – dedicated software/tools | Precise, detailed process models | Complex process modeling, automation | Industry standard, supports execution |

| Process Flow Analysis | Medium to High – analytical focus | High – data and skill intensive | Data-driven process optimization | Performance measurement, bottleneck ID | Quantitative, objective decision making |

| Customer Journey Mapping | Medium – requires customer input | Medium to High – research effort | Improved customer experience | Customer-centric process improvements | Captures emotional and multi-touchpoint views |

| UML Activity Diagrams | High – technical and detailed | High – UML knowledge and tools | Complex logic and parallel flows modeled | IT, software development processes | Models parallel activities, integrates with systems |

| Detailed Process Maps | High – very time-intensive | High – extensive stakeholder involvement | Complete process documentation | Regulated industries, compliance | Thorough detail, supports standardization |

| Lean Process Mapping | Medium – lean training needed | Medium – cultural change effort | Waste reduction and continuous flow | Lean initiatives, waste elimination | Focus on value and waste, continuous improvement |

| Six Sigma Process Mapping (SIPOC) | Low – high-level overview | Low to Medium – team participation | Defined process boundaries and stakeholder clarity | Six Sigma projects, process scoping | Simple, fast, aligns teams on scope and inputs |

Choosing the Right Technique to Engineer Your Success

The journey from operational inefficiency to streamlined excellence is not a single leap but a series of deliberate, well-informed steps. As we have explored throughout this guide, the world of process mapping is rich with diverse methodologies, each offering a unique lens through which to view your organisation’s inner workings. The key takeaway is that there is no universal ‘best’ tool; rather, the power lies in strategic selection. The most effective approach is always the one that directly addresses your most pressing business challenge.

Recapping the Toolkit: Matching the Map to the Mission

Your choice of business process mapping techniques should be purpose-driven. To recap some of the critical decision points we’ve covered:

- For a high-level, universally understood starting point, the classic Flowchart remains an invaluable communication tool.

- When your primary objective is to ruthlessly eliminate waste and shorten cycle times, Value Stream Mapping (VSM) provides a focused, lean perspective.

- To resolve ambiguity and assign clear ownership in complex, cross-departmental workflows, Swimlane Diagrams are unparalleled in their ability to delineate responsibilities.

- If your goal involves technical precision for system integration or complex automation projects, the standardised language of Business Process Model and Notation (BPMN) is essential.

- To understand and enhance the client experience from initial contact to final delivery, Customer Journey Mapping offers critical outside-in insights that other internal-facing maps might miss.

From Blueprint to Action: Your Next Steps

Mastering these concepts transforms process mapping from a theoretical exercise into a dynamic engine for continuous improvement. These visual blueprints are not meant to be static documents filed away and forgotten. They are living tools that should be used to facilitate discussion, drive data-backed decisions, and foster a culture of operational awareness.

Your immediate next step is to diagnose your organisation’s most significant pain point. Are you struggling with project delays? Are customer complaints on the rise? Are operational costs spiralling without a clear cause? Once you have identified the primary problem, select the mapping technique from this guide that is best suited to illuminate its root causes.

Ultimately, the objective of any process mapping initiative extends beyond mere visualisation. The goal is to identify concrete opportunities for improvement, which often involves optimising and automating business processes to unlock new levels of efficiency and strategic advantage. By translating abstract workflows into tangible models, you empower your teams to build a more resilient, scalable, and competitive organisation.

This deliberate approach of mapping, analysing, and refining is the cornerstone of building an enterprise that is not just surviving but is engineered for success.

Ready to turn your process maps into powerful, automated workflows? The expert team at Osher Digital specialises in translating process insights into tangible business outcomes. We design and implement custom automation solutions that reduce manual effort, eliminate errors, and scale your operations for future growth.

Jump to a section

Ready to streamline your operations?

Get in touch for a free consultation to see how we can streamline your operations and increase your productivity.