Business Process Standardisation Success Guide

Master business process standardisation with expert insights, implementation steps, and success metrics for lasting results.

Understanding Business Process Standardisation in Australia

Business process standardisation is a critical strategy for Australian organisations seeking to compete effectively. It’s about establishing consistent, documented procedures for how tasks are executed across an organisation. This consistency yields significant benefits.

For example, standardisation can substantially reduce errors and rework by ensuring everyone adheres to the same best-practice methods. This, in turn, promotes clarity and accountability, simplifying the identification of improvement areas and the measurement of change effectiveness.

This approach is gaining significant traction in Australia. Businesses are increasingly adopting business process standardisation to optimise operations and reduce costs.

One notable case study involves a leading Australian bank that standardised over 2,100 processes. This initiative clarified process ownership and ensured compliance adherence, leading to significant organisational improvements. Discover more insights about process standardisation. This underscores the substantial impact of standardisation on Australian businesses.

Why Standardise Your Business Processes?

Standardisation is not about hindering innovation; it’s about establishing a robust foundation for it. Streamlining core operational activities allows businesses to allocate resources and focus on strategic initiatives.

This can lead to improved customer experiences, accelerated product development cycles, and more agile responses to market changes. Furthermore, standardised processes enhance communication and collaboration by providing a shared language and framework for work.

What Processes Should You Standardise?

Not all processes are equally suited for standardisation. While some greatly benefit from it, others require flexibility. Generally, repetitive, high-volume tasks, like customer onboarding or invoice processing, are ideal candidates.

Standardising these processes can dramatically improve efficiency and minimise errors. However, processes involving creativity or complex problem-solving may require a less rigid structure. Finding the optimal balance between standardisation and flexibility is essential for achieving success.

Building Your Standardisation Strategy That Actually Works

Stop wasting time on strategies that look good on paper but ultimately fail to deliver. This section analyses how successful Australian organisations build standardisation strategies that yield tangible results. This involves a detailed examination of current processes, pinpointing areas for improvement, and actively engaging stakeholders.

Assessing Your Current Processes

Before implementing standardisation, a comprehensive assessment of existing workflows is essential. This requires understanding how work is actually performed, not simply how it is intended to be performed. It’s analogous to planning a road trip: you need to understand the current routes, traffic patterns, and potential detours before charting the optimal course.

-

Identify Key Processes: Start by identifying the core processes driving your business operations. These are the processes directly impacting customer satisfaction, revenue generation, or operational efficiency.

-

Document Current Workflows: Meticulously document each step within these key processes, including any variations or exceptions. This provides a clear snapshot of the current state and highlights areas of inefficiency.

-

Analyse for Bottlenecks: Carefully examine the documented workflows to identify bottlenecks, redundancies, and unnecessary steps. These areas are prime candidates for standardisation.

Prioritising and Engaging Stakeholders

After identifying areas for improvement, prioritisation is paramount. Not all processes require immediate standardisation. Focus on areas with the greatest potential impact.

-

High-Impact Processes First: Begin with processes that offer the most significant returns, whether in terms of efficiency gains, cost savings, or enhanced customer experience.

-

Stakeholder Buy-In: Engage stakeholders early and often. This includes not only management but also frontline staff directly affected by the changes. Clearly explain the benefits of standardisation and address any concerns they may have. This cultivates ownership and minimises resistance.

-

Realistic Timelines: Establish realistic implementation timelines, considering your organisation’s complexities and available resources. A rushed process can result in errors and diminished buy-in.

Building a Governance Structure

Effective governance is vital for sustained success. A well-defined structure ensures consistent adherence to standardised processes and efficient implementation of improvements. Consider the following key elements:

-

Clear Roles and Responsibilities: Clearly define who is responsible for maintaining and updating standardised processes. This eliminates ambiguity and ensures accountability.

-

Regular Process Reviews: Implement a system of regular process reviews to monitor compliance and pinpoint areas for improvement. These reviews serve as regular health checks for your processes.

-

Continuous Improvement Mechanisms: Establish mechanisms for continuous improvement, ensuring your processes adapt to evolving business needs. This allows for ongoing optimisation and adaptation to dynamic market conditions. This might include feedback loops, data analysis, and process adjustments.

Leveraging Outsourcing for Standardisation Success

Australia’s outsourcing sector offers substantial opportunities for business process standardisation. However, capitalising on these opportunities requires a strategic approach. It’s about moving beyond simple cost reduction and towards leveraging partnerships to enhance internal processes. Forward-thinking Australian companies are using outsourcing not just as a cost-cutting tool, but as a catalyst for meaningful operational improvement.

This shift in perspective is key. These companies recognise the strategic value of outsourcing in driving process standardisation. This proactive approach ensures that outsourcing actively contributes to improving internal operations, not simply reducing expenses. For further insight into streamlining business processes, consider this resource: How to streamline business processes.

Preparing Your Processes for Outsourcing

Before engaging an outsourcing partner, internal processes must be clearly defined. This preparation is essential for a smooth transition and maximising the advantages of outsourcing. Much like preparing a house for guests, ensuring everything is organised and in order is crucial for a positive experience.

-

Documentation is Key: Comprehensive process documentation serves as a roadmap for the outsourcing partner. This clarity minimises potential misunderstandings and promotes consistent service delivery.

-

Identify Core Processes: Prioritise the standardisation of core business processes commonly outsourced, such as customer service or data entry.

-

Establish Key Performance Indicators (KPIs): Define the metrics for measuring the success of the outsourced process. These KPIs should align with your overarching business objectives.

Selecting the Right Outsourcing Partner

Choosing the right partner is paramount for standardisation success. Cost is a factor, but the focus should be on partners who understand and align with your standardisation objectives. The growth of the Business Process Outsourcing (BPO) industry in Australia underscores the increasing need for standardised processes. The Australian BPO industry is projected to reach $49.6 billion in revenue by 2025, exhibiting a CAGR of 1.2% over the past five years. This growth reflects a rising demand for outsourced services, many of which depend on standardised processes for efficiency and quality. IBISWorld offers more detailed statistics on this trend.

-

Shared Vision: Partner with providers who understand and support your standardisation goals. A shared vision is the bedrock of a productive and collaborative partnership.

-

Process Expertise: Select partners with a demonstrable track record in the specific processes you intend to outsource. Their expertise can help refine and improve your existing standards.

-

Technology Compatibility: Ensure the partner’s technology infrastructure is compatible with your own. This allows for seamless integration and efficient data exchange.

Building Strong Contracts and Accountability

Contracts should not only protect both parties but actively reinforce process excellence and accountability. A well-structured contract is a cornerstone of a successful outsourcing partnership.

-

Service Level Agreements (SLAs): Incorporate specific SLAs that clearly define performance expectations and any penalties for non-compliance.

-

Regular Reporting: Mandate regular reporting on key performance indicators. This allows you to monitor progress and identify areas for improvement.

-

Continuous Improvement Mechanisms: Integrate mechanisms within the contract for ongoing process review and refinement. This ensures processes remain adaptable and aligned with evolving business needs.

Implementation That Delivers Results, Not Just Documentation

Moving from planning to execution in business process standardisation requires a pragmatic approach. It’s not enough to simply create detailed process maps and documentation. Instead, organisations need an actionable system to transform these plans into tangible business improvements. This section explores practical strategies for implementing standardisation initiatives that genuinely enhance operations.

Documenting Existing Processes Efficiently

Before establishing new standards, it’s essential to gain a thorough understanding of the current state of your business processes. This involves documenting existing workflows, but the key is to avoid unnecessary complexity. Think of it like creating a blueprint: capture the essential structural elements without getting bogged down in minute details. For further reading on this subject, see How to master process documentation.

-

Focus on Core Processes: Start by documenting the most critical processes – those with the most significant impact on customer satisfaction, revenue generation, or operational efficiency.

-

Collaborate with Frontline Staff: Engage with the employees who execute these processes daily. Their practical, on-the-ground insights are invaluable for accurately capturing the reality of how work is performed.

-

Use Visual Aids: Visual representations, like flowcharts and diagrams, can greatly enhance understanding and communication of complex workflows.

Defining and Implementing New Standards

Once current processes are documented, the next step is analysis. This phase focuses on pinpointing areas for improvement and developing new, standardised procedures that are both practical and user-friendly.

-

Keep it Simple: Avoid overly complicated standards. The objective is to simplify work, not add layers of bureaucracy. Standards should be clear, concise, and easily accessible to all involved parties.

-

Solicit Feedback: Actively involve employees in the development of new standards. Their feedback is critical for ensuring the standards are realistic, workable, and promote buy-in, reducing potential resistance to change.

-

Pilot Test New Standards: Before a full-scale implementation, conduct pilot tests in a controlled environment. This allows for identification of potential problems and adjustments before rolling out the standards across the organisation.

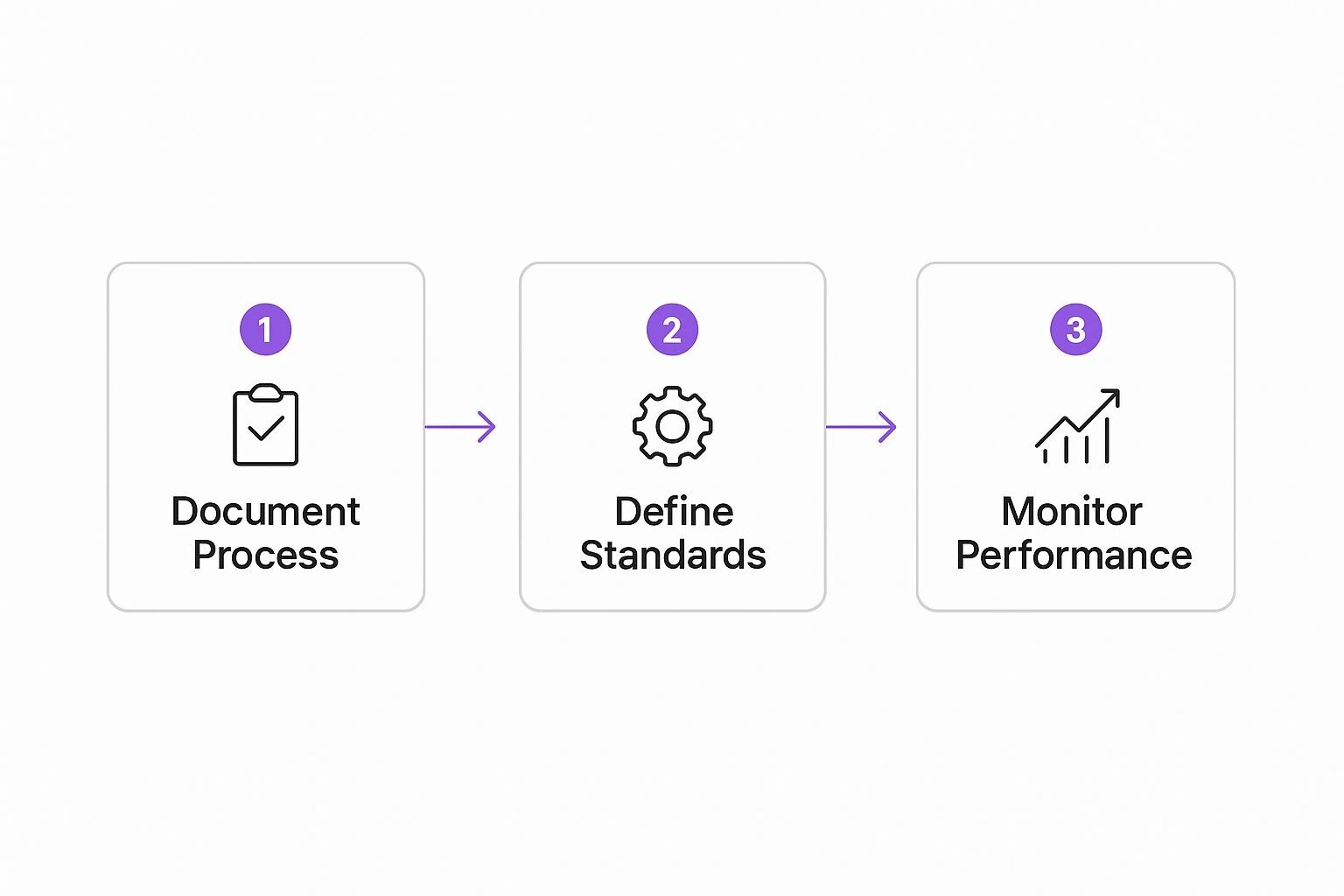

This infographic provides a visualisation of the core workflow for successful business process standardisation. It emphasises the key phases: documenting existing processes, defining new standards, and implementing ongoing performance monitoring. The interconnectedness of these phases highlights the need for a continuous cycle of improvement.

To provide further insight into the implementation process, the following table details the key phases and activities:

| Process Standardisation Implementation Phases | Implementation Phase | Duration | Key Activities | Success Metrics | Common Challenges |

|---|---|---|---|---|---|

| Process Mapping & Documentation | 2-4 Weeks | Documenting current processes, conducting stakeholder interviews, creating process maps | Number of processes documented, stakeholder engagement, completeness of documentation | Resistance to change, lack of documentation, unclear processes | |

| Standards Development | 4-6 Weeks | Defining new standards, developing procedures, soliciting employee feedback | Clarity of standards, employee feedback, feasibility of implementation | Difficulty reaching consensus, overly complex standards, lack of buy-in | |

| Pilot Testing | 2-4 Weeks | Testing new standards in a controlled environment, collecting data, making adjustments | Performance against metrics, identification of issues, successful implementation in pilot group | Limited scope of pilot, resistance from pilot group, difficulty extrapolating results to wider organisation | |

| Implementation & Rollout | 4-8 Weeks | Training employees, communicating new standards, implementing across the organisation | Adoption rate, performance against metrics, reduction in errors/processing time | Resistance to change, lack of training, technical issues | |

| Monitoring & Refinement | Ongoing | Tracking performance, gathering feedback, making adjustments as needed | Continuous improvement in key metrics, employee satisfaction, improved efficiency | Difficulty tracking metrics, lack of resources, changing business needs |

This table outlines the various phases involved in implementing process standardisation, including estimated durations, key activities within each phase, success metrics for measuring progress, and potential challenges to address. Understanding these components is crucial for managing the implementation effectively and achieving lasting results.

Monitoring Performance and Ensuring Adoption

Successful implementation extends beyond the initial rollout. Ongoing monitoring is vital for ensuring new standards are adopted and deliver the intended results. This involves tracking key performance indicators (KPIs), proactively addressing challenges, and adapting standards as needed.

-

Establish Clear Metrics: Define specific, measurable metrics to track the impact of standardisation. This could involve measuring error rates, processing time, or customer satisfaction levels.

-

Regularly Review Performance: Conduct regular performance reviews against the established metrics. This process facilitates the identification of both successful areas and areas requiring improvement.

-

Provide Ongoing Support and Training: Ensure employees have access to the necessary resources and training to effectively implement new standards. Address any questions or concerns promptly to promote adoption and minimise disruption. This commitment fosters a culture of continuous improvement, allowing processes to evolve and adapt to the ever-changing business landscape.

Technology and Environmental Drivers Shaping Success

The Australian business landscape is constantly evolving. Technological advancements and organisational shifts present a complex interplay of challenges and opportunities. Astute organisations are leveraging these changes through the strategic implementation of business process standardisation. This proactive approach is key to achieving sustained success in today’s dynamic market.

IT Advancements and The Need for Standardisation

The rapid expansion of the IT and telecommunications sector within Australia is a major catalyst for this trend. Industries with demanding operational efficiency needs and strict regulatory compliance requirements are particularly impacted.

The financial services industry, for example, is increasingly dependent on standardised processes to maintain accuracy and security in its transactions. This emphasis is further reinforced by the growing adoption of cloud computing and automation.

Environmental and organisational factors also play a role in the increasing adoption of process standardisation across Australia. The Australian Bureau of Statistics (ABS), for instance, has been implementing significant changes to enhance operational efficiency. These likely involve process standardisation initiatives aligned with evolving technological and organisational strategies. The continued growth of the IT and telecommunications sector is expected to further drive demand for specialised services, which often require standardised processes. Further research on this topic is available.

Balancing Standardisation With Flexibility

Standardisation, however, must be carefully balanced with the need for flexibility and innovation. Australian businesses operate in a climate of rapid market changes, necessitating agility and adaptability. An overly rigid, standardised approach can stifle responsiveness to evolving customer needs and emerging market trends.

Organisations, therefore, must strategically select which processes to standardise. Processes well-suited for standardisation are typically repetitive, high-volume tasks. Examples include invoice processing and customer onboarding. Conversely, processes that rely on creativity or complex problem-solving may benefit from a more flexible framework.

Leveraging Technological Change for Process Improvement

Technological change offers substantial opportunities for process improvement. Automation, for instance, can streamline repetitive tasks, minimising errors and freeing up personnel for more strategic activities. Data analytics tools offer valuable insights into process performance, highlighting bottlenecks and areas for optimisation.

Cloud-based platforms also facilitate greater collaboration and information sharing, further enabling standardised processes across geographically dispersed teams. By strategically embracing these technological advancements, Australian organisations can transform operational hurdles into opportunities for growth and enhanced efficiency. This not only entails adopting new technologies but also adapting existing processes and organisational structures. This holistic approach is vital for maintaining competitiveness in the ever-changing Australian business environment and ensuring future success.

Measuring Success and Maintaining Long-Term Excellence

Business process standardisation isn’t a one-time project. It requires continuous monitoring and refinement to ensure long-term success. This means establishing robust measurement systems that reflect real business impact, not simply process compliance. This section offers guidance on establishing meaningful metrics and maintaining a culture of process excellence within Australian businesses.

Defining Key Performance Indicators (KPIs)

Selecting the right Key Performance Indicators (KPIs) is crucial. These metrics should directly align with your business objectives and provide quantifiable measurements of the impact of your standardisation efforts. For example, if a goal is to improve customer satisfaction, a relevant KPI might be the Net Promoter Score (NPS).

Additionally, don’t neglect qualitative indicators. While numbers provide valuable data, feedback from staff and customers provides richer context and deeper insights into the effectiveness of standardised processes. This feedback can reveal unforeseen challenges or unintended consequences of standardisation, allowing for timely adjustments. You might be interested in: How to master business process improvement.

To illustrate the types of KPIs that businesses can use to track the success of their process standardisation efforts, the following table provides examples, target ranges, and measurement frequencies. Understanding these metrics is crucial for evaluating the effectiveness of any standardisation initiative.

Introducing the table below, which details key performance indicators essential for gauging the success of process standardisation initiatives. The table offers benchmarks and measurement frequencies for various metrics across different KPI categories.

| KPI Category | Specific Metrics | Target Range | Measurement Frequency | Business Impact |

|---|---|---|---|---|

| Efficiency | Cycle Time Reduction | 10-20% | Monthly | Reduced operational costs |

| Efficiency | Error Rate | < 1% | Weekly | Improved quality control |

| Customer Satisfaction | NPS | 60-70 | Quarterly | Increased customer loyalty |

| Customer Satisfaction | Customer Complaint Resolution Time | < 24 hours | Daily | Enhanced customer experience |

| Employee Performance | Employee Productivity | 5-10% increase | Monthly | Improved workforce efficiency |

| Employee Performance | Employee Satisfaction with Processes | 4.0-5.0 (on a 5-point scale) | Annually | Increased employee morale |

This table summarises key metrics for assessing the impact of process standardisation. By regularly monitoring these KPIs, businesses can gain valuable insights into the effectiveness of their initiatives and make data-driven adjustments to optimise performance.

Monitoring for Process Drift

Even with well-defined standards, process drift – the gradual deviation from established procedures – can occur. This is often a result of changes in personnel, technology, or business priorities. Regular monitoring is essential to detect and address this drift before it negatively impacts performance.

-

Establish Regular Audits: Implementing a system of regular process audits provides objective assessments of adherence to standards and pinpoints areas where processes have veered off track.

-

Real-Time Data Tracking: Whenever possible, utilise technology to track process performance in real time. This enables the immediate identification of deviations and facilitates prompt corrective action.

-

Employee Feedback Loops: Encourage staff to regularly provide feedback on standardised processes. They are often the first to notice inefficiencies or misalignments with business needs.

Continuous Improvement and Adaptation

Business needs and regulations are constantly evolving. Your standardised processes must be adaptable to maintain relevance and effectiveness. This necessitates a culture of continuous improvement and a system for regular review and updates.

-

Scheduled Process Reviews: Conduct regular, scheduled reviews of standardised processes, including stakeholders from across the organisation to obtain a comprehensive perspective.

-

Change Management Protocols: Establishing clear protocols for managing process changes ensures that updates are properly documented, communicated, and implemented effectively.

-

Training and Development: Offer ongoing training and development opportunities related to standardised processes, empowering staff to actively participate in process improvement and ensuring consistent application of updated procedures.

Building a Culture of Process Excellence

Ultimately, long-term success hinges on building a culture of process excellence. This transcends simply adhering to procedures. It requires cultivating an environment where all employees understand the value of standardisation and actively contribute to its ongoing improvement.

This can be achieved through clear communication, recognising and rewarding process improvement contributions, and providing opportunities for staff involvement in these initiatives. By embedding process excellence into the organisational culture, businesses ensure their standardisation efforts continue delivering value and supporting growth. This not only improves operational efficiency but strengthens the overall organisational structure, creating a more adaptable and resilient business.

Your Practical Next Steps for Getting Started

Transforming your organisation through business process standardisation requires a structured approach. This section provides a practical roadmap designed for Australian businesses, offering clear, prioritised steps to begin implementation, regardless of your organisation’s size or current process maturity.

Securing Buy-In and Allocating Resources

Begin by securing leadership support. Clearly articulate the benefits of standardisation, focusing on tangible outcomes like increased efficiency and reduced costs. This is about presenting a compelling case for change, not overselling a concept.

Allocating resources effectively is the next critical step. Even with budget constraints, prioritise areas where standardisation will yield the highest return. Start small, focusing on high-impact processes, then gradually expand as you demonstrate success.

Building Internal Capability and Selecting the Right Tools

Developing internal expertise is crucial for long-term success. Investing in training your team on process mapping, analysis, and improvement methodologies empowers them to take ownership of the standardisation journey.

Choosing the right tools and technologies is equally important. Select solutions that simplify process documentation and automation, avoiding those that add complexity. Focus on user-friendly platforms that integrate seamlessly with your existing systems.

Creating Sustainable Practices and Avoiding Common Pitfalls

Standardisation is not a one-time project; it’s an ongoing process. Establishing mechanisms for regular review and updates ensures your standards remain relevant and effective in the long run.

Avoid common pitfalls such as overly complex documentation or insufficient staff training. These obstacles can hinder adoption and reduce the overall impact of your standardisation efforts. Focus on building a culture of continuous process improvement, where standardised processes are not just followed, but actively refined and optimised.

Ready to streamline and scale your operations? Osher Digital offers business process automation and AI-driven solutions designed to empower Australian businesses. Visit Osher Digital today to learn more.

Jump to a section

Ready to streamline your operations?

Get in touch for a free consultation to see how we can streamline your operations and increase your productivity.