Operational Excellence Framework

Explore how our operational excellence framework can transform your business. Learn models and steps for sustainable success in Australia.

Think of an operational excellence framework as the architectural blueprint for a truly high-performance organisation. This isn’t just about a single tool or some passing business trend; it’s the entire ecosystem of principles, methods, and cultural values that steers your business toward delivering exceptional value to your customers, every single time.

Unpacking the Blueprint for Organisational Success

Imagine your framework is a sophisticated GPS for your business. It doesn’t just point to a destination: superior customer value and market leadership. It gives you the turn-by-turn directions, the real-time traffic updates, and even the alternative routes needed to navigate the inevitable challenges you’ll face along the way.

This system is about moving beyond simple cost-cutting exercises or isolated efficiency gains. Instead, it’s about cultivating a holistic environment where continuous improvement becomes second nature to every single employee, from the front line to the executive team.

A System of Principles and Actions

At its heart, a solid framework integrates several core components that must work in concert to drive performance. These aren’t standalone initiatives but interconnected pillars that support the entire structure. The aim is to build a culture where problems are treated as opportunities for improvement, not reasons to point fingers.

A big part of this involves getting to grips with what your customers truly value. From there, you can meticulously align every single process to deliver that value as efficiently as possible. A powerful tool for this is visualising your workflows through business process mapping techniques, which are brilliant for spotting and eliminating waste. This ensures every action taken contributes directly to the end goal.

The fundamental pillars of a framework provide the structure needed for this kind of systematic improvement. They form the foundation upon which a culture of excellence is built.

Core Components of an Operational Excellence Framework

| Component | Description |

|---|---|

| Culture of Improvement | Fostering an environment where every employee is engaged, empowered, and actively seeks opportunities to enhance processes and customer value. |

| Customer Focus | A deep, data-informed understanding of customer needs and expectations, which guides all strategic decisions and process designs. |

| Process Management | Systematically designing, managing, and improving end-to-end business processes to eliminate waste, reduce variability, and increase speed. |

| Data-Driven Decisions | Using metrics and analytics to objectively assess performance, identify root causes of problems, and validate the impact of improvements. |

| Strategic Alignment | Ensuring that all improvement efforts are directly linked to the organisation’s overarching strategic goals and vision. |

These components work together to create a self-reinforcing cycle of improvement, pushing the organisation towards sustained success.

The Strategic Imperative for Australian Businesses

For Australian organisations, adopting a robust operational excellence framework is no longer just a “nice-to-have”: it’s a strategic necessity for survival and growth. While data-driven decision-making is a key part of any modern framework, there’s a troubling disconnect happening.

Surveys of Australian operational leaders show that a staggering 91% struggle to extract actionable insights from their data to make critical decisions. This reveals a significant gap between ambition and reality. You can explore more on the challenges facing local businesses from the Process Excellence Network.

An operational excellence framework ensures that every employee, from the front line to the executive suite, can clearly see, deliver, and improve the flow of value to the customer. It builds a resilient, competitive, and constantly improving organisation.

This is precisely why a structured approach is so critical. Without a guiding framework, improvement efforts often become disjointed, any gains are temporary, and the organisation fails to build the momentum needed for lasting change. It’s the roadmap that turns ambition into tangible, sustainable results and cements a company’s position as a leader in its market.

Here is the rewritten section, designed to sound like it was written by an experienced human expert.

The Guiding Principles of Operational Excellence

Any solid operational excellence framework is more than just a toolkit; it’s a philosophy. These core principles are the bedrock of the entire system, shaping the culture and guiding every decision. They are the “why” that fuels the “how,” nurturing a mindset geared for continuous improvement and long-term success.

Getting your head around these principles is the first real step towards building a system where excellence isn’t an occasional goal, but just the way things are done. It’s about making a fundamental shift away from a reactive, fire-fighting culture to one that proactively improves its own systems. For any framework to stick, these ideas need to be lived and breathed by leadership and genuinely adopted by everyone in the organisation.

Create Unwavering Customer Value

Ultimately, every single operational excellence initiative has one end-game: delivering maximum value to the customer. This principle forces you to scrutinise every activity through your customer’s lens. If a process, task, or feature doesn’t contribute something the customer actually cares about, and would willingly pay for, it’s essentially waste.

Think about a Sydney-based financial services firm. Internally, they might be proud of their complex, multi-stage loan approval process, believing it guarantees accuracy. But what if their customers’ main priorities are speed and simplicity? In that case, the firm’s elaborate process isn’t adding value; it’s destroying it. The real challenge is to redesign the process to be both fast and accurate, aligning their internal definition of quality with what the customer truly values.

At its heart, operational excellence is about a relentless obsession with the customer. It’s about knowing precisely what they need, understanding their perception of value, and then aligning every single process to deliver on that expectation flawlessly.

This customer-first viewpoint acts as the North Star for all improvement efforts. It makes sure teams aren’t just getting better at doing the wrong things. Instead, they’re optimising the right activities that directly improve the customer experience and foster genuine loyalty.

Focus on the Process, Not the People

When something goes wrong, our first instinct is often to point a finger. An operational excellence mindset completely rejects this blame game. It works from a different assumption: that faulty systems and broken processes, not careless individuals, are the true culprits behind most mistakes.

This change in perspective is massive. When people live in fear of being blamed, they hide problems. This means systemic flaws never see the light of day and only get worse over time. By focusing on the process, you create a safe environment where people can actually solve problems.

Imagine a logistics company in Western Australia struggling with a high rate of incorrect shipments.

- The Blame Approach: A manager might haul the specific warehouse workers over the coals, assuming they were careless. This just creates fear and resentment, and the problem will happen again next week.

- The Process Approach: The team digs into the entire shipping process from start to finish. They might find the labelling software is clunky, the picking slips are confusing to read, or the warehouse layout itself is causing mix-ups.

By fixing the system, perhaps by rolling out clearer labelling and reorganising the warehouse for a more logical flow, the company makes it much harder for that error to happen again, no matter who is on shift. This is a far more powerful and lasting solution than just blaming an employee.

Respect for Every Individual

This principle goes much deeper than simply being polite. It’s about a genuine belief that every single person in the organisation, from the C-suite to the front line, has unique knowledge and the capacity to improve the business. Real respect is shown by actively involving people in making the work they do every single day better.

Empowering your people means you have to:

- Provide Training: Give them the skills and tools they need to spot issues and test out solutions.

- Seek Input: Genuinely listen to their ideas and frustrations about the processes they know inside-out.

- Give Ownership: Let teams experiment with improvements and take real responsibility for their part of the operation.

When people feel respected and trusted, they become invested and proactive. They are the ones closest to the action and, more often than not, have the most practical ideas for improvement. An operational excellence framework absolutely depends on tapping into this collective brainpower to move forward. Without it, you’re just left with a top-down mandate that’s doomed from the start.

Choosing Your Operational Excellence Model

Picking an operational excellence framework is a bit like choosing the right strategy for a major renovation. You wouldn’t use the same tools and plans for a cosmetic update as you would for a foundational restructuring. There’s no single “best” model; instead, you have a collection of proven approaches, each with its own focus. The real skill lies in matching the right framework to your organisation’s specific challenges and goals.

Just as a master craftsperson knows when to use a fine-grit sandpaper versus a sledgehammer, a savvy leader needs to diagnose their business’s pain points accurately. Are you grappling with painfully long lead times and convoluted processes? Or is inconsistent quality and a high defect rate your main headache? Your answer points the way to the most suitable model.

Lean: The Pursuit of Flow and Waste Elimination

At its heart, Lean is all about a relentless quest to find and eliminate waste, all while smoothing out the flow of value to the customer. “Waste,” in this context, isn’t just about throwing things in the bin. It’s any activity that uses up resources: time, money, materials, but adds zero value from the customer’s perspective. It’s about making things simpler, faster, and more efficient.

Think of a Melbourne-based e-commerce retailer. A Lean approach would start by mapping out the entire journey of an order, from the moment a customer clicks “buy” to the package landing on their doorstep. The team would then put every single step under the microscope, asking tough questions:

- Waiting: How long do paid orders sit in a queue before being picked?

- Over-processing: Are we using three layers of bubble wrap when one would do the job safely?

- Defects: How often do we send the wrong item, forcing costly returns and frustrating customers?

- Motion: Are our warehouse staff walking kilometres every day just to fetch popular products?

By systematically rooting out these wasteful activities, the retailer doesn’t just cut costs. They dramatically shorten delivery times, which directly boosts the customer experience. Lean is a fantastic fit for any organisation that needs to inject more speed, efficiency, and responsiveness into its operations.

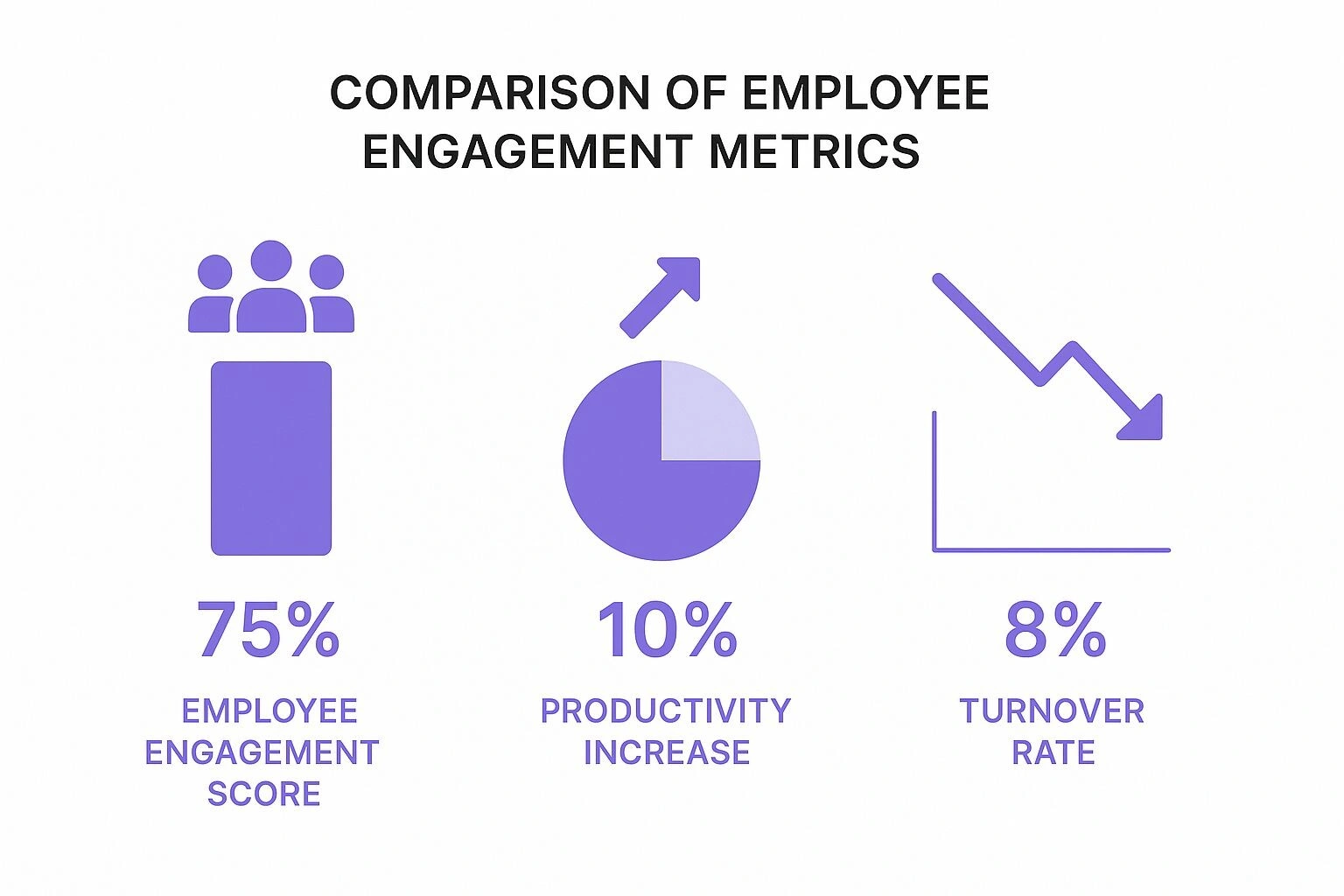

The infographic below shows how getting these models right can have a powerful, positive ripple effect on your team, the very people needed to sustain any improvement culture.

The data here really drives home the link between an engaged workforce, better productivity, and lower staff turnover: all common and highly desirable outcomes of a well-run operational excellence program.

Six Sigma: The Drive for Quality and Consistency

While Lean is obsessed with speed and flow, Six Sigma is a data-driven methodology laser-focused on crushing variation and eliminating defects. The entire goal is to make your processes so consistent and predictable that the output is almost perfect, every single time. A process running at a Six Sigma level produces fewer than 3.4 defects per million opportunities.

This model shines in environments where precision is non-negotiable. Take a medical device manufacturer in Adelaide, for instance. A tiny, almost imperceptible variation in a component could have life-altering consequences. Six Sigma provides the statistical toolkit, most famously the DMAIC (Define, Measure, Analyse, Improve, Control) cycle, to dig deep, find the root causes of that variability, and implement rock-solid controls to stop defects before they even happen.

Six Sigma is about the pursuit of near-perfection. It swaps guesswork and gut feelings for rigorous statistical analysis, ensuring that what you produce is reliable, repeatable, and consistently meets the highest quality standards.

It’s especially potent in manufacturing, finance, and healthcare: any field where the cost of an error is incredibly high and consistency is everything.

The Shingo Model: The Focus on Culture and Principles

Where Lean and Six Sigma are heavy on tools and processes, the Shingo Model takes a different tack. It’s a framework built around establishing a sustainable culture of excellence through guiding principles. The core idea is simple but profound: ideal results require ideal behaviours, and the right principles are what shape those behaviours. The model organises these principles across four dimensions: Cultural Enablers, Continuous Improvement, Enterprise Alignment, and Results.

For a large services firm in Brisbane looking to make a deep, lasting cultural shift, the Shingo Model provides a philosophical compass. It steers the conversation away from just “which tool should we use?” and towards more fundamental questions:

- Are our leaders actively showing respect for every individual on the team?

- Is every part of our business aligned around creating genuine customer value?

- Have we established a constancy of purpose that everyone in the organisation understands and believes in?

The Shingo Model is less of a step-by-step manual and more of a guiding philosophy. It’s often used to strengthen other models like Lean, ensuring that the improvements aren’t just superficial process changes but are woven into the very fabric of the organisation’s culture. It helps build the foundation upon which all other tools can deliver long-term, sustainable success.

Comparison of Operational Excellence Models

To help you see how these frameworks stack up at a glance, the table below offers a high-level comparison. Think of it as a quick reference guide to help you start thinking about which approach, or combination of approaches, might be the best fit for your situation.

| Model | Primary Focus | Key Tools | Best For |

|---|---|---|---|

| Lean | Eliminating waste, improving speed and process flow. | Value Stream Mapping, 5S, Kanban, Kaizen. | Improving efficiency, reducing lead times, and increasing responsiveness. |

| Six Sigma | Reducing defects and process variation through data analysis. | DMAIC cycle, Statistical Process Control (SPC), Root Cause Analysis. | High-precision environments like manufacturing, healthcare, and finance. |

| The Shingo Model | Building a sustainable culture of excellence based on principles. | Guiding Principles, Behavioural Benchmarks, Gemba Walks. | Driving deep cultural transformation and providing a foundation for other models. |

Each model offers a unique lens through which to view your operations. The most successful organisations often don’t just pick one; they thoughtfully blend principles and tools from different models to create a customised approach that addresses their unique operational DNA.

How to Implement Your Operational Excellence Framework

Moving from theory to practice is where the real work begins. Choosing a model is one thing, but actually implementing an operational excellence framework is a major undertaking that requires a clear, practical roadmap. This isn’t just another project with a start and end date; it’s the beginning of a long-term cultural shift towards high performance.

A successful rollout follows a logical sequence. It starts with getting your leadership team on board and tying the whole initiative to your core business strategy. From there, you can dip your toes in the water with targeted pilot programs before you even think about a company-wide deployment. You’ll hit bumps along the way, but with the right game plan, they’re entirely manageable.

Secure Leadership Buy-In and Strategic Alignment

Before you touch a single process, the framework needs rock-solid support from the top. Leadership buy-in is the non-negotiable foundation for any successful implementation. Your executives need to do more than just sign off on the budget; they have to become visible champions for the change, constantly communicating why it’s so important.

This alignment ensures the framework is seen as a core part of the company’s strategy, not just another flavour-of-the-month idea from the operations team. When leaders can clearly connect operational excellence to achieving major business goals, everyone else has a compelling reason to get on board.

This is especially true in the Australian business environment, where overcoming digital transformation challenges is now deeply linked to operational strength. As detailed in insights from CIO Edge, a strategic path to technology leadership hinges on a culture of continuous improvement, backed by data-driven operations and a laser focus on the customer.

Start Small with Targeted Pilot Programs

Trying to change everything at once, a “big bang” implementation, is a classic recipe for disaster. It causes massive disruption, stretches your people too thin, and creates far more problems than it solves. A much smarter approach is to start with a few targeted pilot programs.

Look for a specific part of the business that’s feeling real pain. It could be a single department struggling with long lead times or one particular value stream that’s plagued by high error rates. This is your perfect testing ground.

A pilot program lets you test your chosen framework in a controlled, low-risk environment. It’s your chance to work out the kinks, prove the value with hard data, and build the momentum you’ll need for the broader rollout.

A successful pilot acts as your internal proof of concept. The positive results and the lessons you learn become a powerful case study you can use to get other teams excited and lower their resistance to the changes ahead.

Navigating Common Implementation Roadblocks

Even with the best planning in the world, you’re going to run into challenges. The key is to anticipate them so you can navigate them effectively when they appear.

Two of the most common hurdles you’ll face are:

- Employee Resistance: Change is uncomfortable. People might be sceptical, worried their jobs are at risk, or simply resistant to learning a new way of working. The best way to handle this is with open, transparent communication. Involve them in the process, provide excellent training, and show them how the changes will make their work less frustrating and more rewarding.

- Resource Constraints: You can’t achieve operational excellence on a shoestring budget. It requires a real investment of time, money, and your best people. It’s crucial to build a strong business case that clearly outlines the expected return on that investment, whether it’s cost savings from eliminating waste or more revenue from happier customers.

Tackling these issues head-on will make for a much smoother journey. This is where strong project and change management skills become your most valuable assets.

Execute a Phased Rollout and Integrate Systems

Once your pilot program has delivered results, you can start a phased rollout across the rest of the organisation. Use what you learned from the initial test to fine-tune your approach for the next stage. This gradual expansion lets you manage the change in bite-sized pieces, ensuring every team gets the focus and support they need to succeed.

A critical part of this phase is making sure your technology can keep up with your new processes. As you redesign workflows, your different systems need to talk to each other seamlessly. Following system integration best practices is essential here to prevent data silos and ensure information flows freely across your newly optimised operations.

Remember, the goal isn’t just to “complete the implementation.” The true aim is to weave the principles of your framework into the daily fabric of the organisation, making continuous improvement the default way everyone works.

How Operational Excellence Fuels AI Success

Artificial intelligence is often talked about as a silver bullet for productivity, but that perspective misses a crucial detail. The success of any AI tool isn’t magic; it’s entirely dependent on the quality of the processes it’s given and the data it analyses. Dropping powerful AI into a business riddled with chaos and inefficiency is just a fast track to expensive failure.

This is where a mature operational excellence framework becomes non-negotiable. It essentially preps the organisation for AI by standardising processes, cleaning up data, and systematically rooting out waste before you even start looking at automation. In other words, operational excellence ensures you’re amplifying what already works, not just automating chaos at a frightening new speed.

Creating a Solid Foundation for AI

Think of AI as a high-performance engine. You wouldn’t drop a Formula 1 engine into a car with a rusted chassis, bald tyres, and a dodgy steering rack. First, you’d build a vehicle that could actually handle that kind of power. An operational excellence framework is how you reinforce your organisation’s chassis.

This foundational work is so important because AI learns from and acts upon your existing systems. If your data is a mess, inconsistent, incomplete, or siloed across departments, your AI algorithms will churn out flawed insights and make poor decisions. It’s that simple. Likewise, if your workflows are full of hidden bottlenecks and redundant steps, automating them won’t solve the underlying problems; it will just hide them under a veneer of technology.

For businesses in Australia, getting this foundation right has become a critical first step. The journey starts with getting a firm grip on your operations to understand what your business is truly capable of. Only then can you begin to embed automation and data-driven practices effectively. Research clearly shows that Australian organisations achieving ‘AI Ready’ status through operational excellence are the ones best positioned to unlock significant financial and productivity gains. You can delve deeper into this journey through a detailed analysis of AI success in the Australian context on enlighten-opex.com.au.

Turning Technology Investment into Real Productivity

Companies that get a handle on continuous improvement first are in a unique position to turn AI into a genuine competitive advantage. They have already built a culture that knows how to spot waste and optimise how value is delivered to the customer.

AI doesn’t create operational excellence; it scales it. A business that is already efficient, customer-focused, and data-driven will see exponential returns from AI. A disorganised one will only see its existing problems magnified.

When you apply AI to a well-oiled machine, the results can be profound.

- Predictive Maintenance: In a manufacturing plant with optimised production lines, AI can analyse sensor data to predict equipment failure before it happens, preventing enormously costly downtime.

- Intelligent Automation: For a company with streamlined financial processes, AI can automate invoice processing and reconciliation with near-perfect accuracy, freeing up the finance team for more strategic work.

- Enhanced Customer Service: With clean and integrated customer data, AI-powered chatbots can resolve queries with incredible speed and precision, lifting customer satisfaction.

The synergy between operational excellence and artificial intelligence becomes undeniable when you look at real-world examples. Understanding how AI is transforming field service operations shows just how much more effective AI becomes when logistics and scheduling are optimised first. It proves that investing in an operational excellence framework isn’t just another cost, it’s the essential enabler for turning technology spending into real, measurable productivity gains.

Measuring and Sustaining Your Progress

Launching an operational excellence initiative without a way to measure it is like flying a plane without an instrument panel. You’re definitely moving, but you have no real idea if you’re heading in the right direction, gaining altitude, or about to run out of fuel.

To turn your efforts from a hopeful exercise into a source of tangible results, you need a balanced way to track the real-world impact. This is about moving beyond gut feelings and embracing hard data. The trick is to develop a suite of Key Performance Indicators (KPIs) that gives you a complete picture of your performance, not just a single, potentially misleading snapshot.

Establishing Your Key Performance Indicators

Focusing only on one area, like cost cutting, can often have disastrous effects elsewhere, such as plummeting product quality or tanking customer satisfaction. A truly effective operational excellence framework tracks success across multiple dimensions to prevent this.

To get that complete picture, your measurement system should draw from several critical areas. This approach ensures your improvements in one part of the business aren’t accidentally causing problems in another.

A well-rounded set of metrics typically includes:

- Operational Metrics: These KPIs get right to the heart of your process efficiency. Think of things like cycle time (the total time from start to finish for a process), first-time quality (the percentage of work that’s perfect on the first attempt), and Overall Equipment Effectiveness (OEE) for manufacturing.

- Financial Metrics: This is where you track the bottom-line impact. The obvious ones are cost savings from eliminating waste and increased revenue from better capacity. But don’t forget to measure the Return on Investment (ROI) for specific improvement projects to justify the effort.

- Customer-Focused Metrics: This is where the rubber really meets the road: measuring what your customers actually care about. Keep a close eye on Customer Satisfaction Scores (CSAT), Net Promoter Score (NPS), and on-time delivery rates. These tell you if your internal changes are creating genuine external value.

Sustaining Momentum for the Long Haul

Once you start seeing positive results, the next, and perhaps bigger, challenge is keeping the momentum going. The initial buzz of any new initiative eventually fades. That’s why you need to weave sustaining rituals into the daily fabric of your organisation. This is how operational excellence stops being a “project” and becomes “just how we do things around here.”

Lasting success isn’t achieved through a single, grand transformation. It is the result of countless small, consistent actions and rituals that reinforce a culture of continuous improvement every single day.

One of the most powerful tools for this is the visual management board. This could be a physical whiteboard in a common area or a shared digital dashboard, but its purpose is the same: to display your key KPIs for everyone to see. It makes progress, or a lack of it, impossible to ignore and becomes the focal point for regular team huddles.

These brief, daily or weekly huddles aren’t your typical long, drawn-out meetings. They are quick, stand-up check-ins where the team reviews the metrics, tackles roadblocks, and celebrates small wins. This constant feedback loop keeps everyone engaged and focused on what matters. To explore this further, our guide on business process improvement offers practical strategies for refining your workflows.

Finally, never underestimate the power of recognition. Acknowledging the teams and individuals who drive improvements is crucial. It reinforces the behaviours you want to see and fuels the motivation needed to ensure your framework delivers value for years to come.

Frequently Asked Questions

As you start exploring operational excellence, it’s natural for a few key questions to pop up. Getting these frameworks off the ground involves real-world practicalities, so let’s tackle some of the most common queries we hear from organisations just like yours.

How Long Does It Take To See Results?

This is the big one, and the honest answer is: it depends. The timeline for seeing real, measurable results hangs on the scope of your first projects and where your organisation is starting from.

You can definitely score some quick wins. A focused pilot program can start showing results, like shorter cycle times in one department or better quality on a single product, in as little as three to six months. But making continuous improvement a part of your company’s DNA? That’s the long game. A true, organisation-wide cultural shift often takes several years to really take hold.

What Is The Biggest Challenge When Implementing a Framework?

You might think the hardest parts are finding the budget or getting the tech right, but the biggest hurdle is almost always the people-side of things. The toughest battles are overcoming resistance to change and getting genuine, unwavering commitment from leadership.

So many of these initiatives don’t fail because the model was flawed. They fail because the culture wasn’t ready.

Even the most perfectly designed operational excellence framework is doomed if your team sees it as just another flavour-of-the-month mandate from the top. Success lives or dies on building an environment of psychological safety, where people feel empowered to flag problems and suggest fixes without pointing fingers.

Can Small Businesses Use an Operational Excellence Framework?

Absolutely. The term might sound like it’s just for corporate giants, but the principles themselves are universal. A small business can gain a massive advantage by focusing on what its customers truly value, ruthlessly cutting out waste, and empowering its team.

The trick for a small business is to keep things simple. You don’t need a massive toolkit. Just start by mapping out one critical process and get your team in a room to brainstorm how to make it better. That laser focus on efficiency and customer happiness can be a huge competitive edge for any smaller player.

At Osher Digital, our specialty is bringing the principles of operational excellence to life with smart automation. If you’re ready to cut out waste and find a new gear of efficiency, we build the automated solutions that fuel your growth.

See how we can help transform your operations by visiting our website at https://osher.com.au.

Jump to a section

Ready to streamline your operations?

Get in touch for a free consultation to see how we can streamline your operations and increase your productivity.